With the rise in conscious fashion, both consumers and businesses are turning towards less polluting and more sustainable options when it comes to products and raw materials. In light of the same, we have seen an increase in the number of next-gen materials or alternatives to leather that come in the form of lab-grown variants, and naturally-derived vegan variants, be it mushroom leather (MycoWorks) or pineapple leather (Piñatex ®), among others. But now we have a new kid on the block that claims to actually help address the ecological imbalance created unintentionally by humans several decades ago.

Three experienced divers might have just come out with a solution to tackle the polluting and unethical impact of leather. Made from invasive species such as Lionfish, Florida-based start-up Inversa’s highly durable fish leather is helping to solve the environmental crisis and also protect biodiversity at the same time.

‘For the first time, products can be more than just ‘less bad’. Each (Lionfish) hide saves up to 70,000 native reef fish and actively heals our planet,’ the company states on its website.

Native to the Indian and Pacific oceans, the lionfish species did not pose any danger to the oceans until a handful of them were slipped undetected into Atlantic waters off the coast of Florida as a result of human error in the late 1980s.

Inversa creates leather from predatory lionfish, transforming them into beautiful, durable leather that can be used in shoes, accessories and other products.

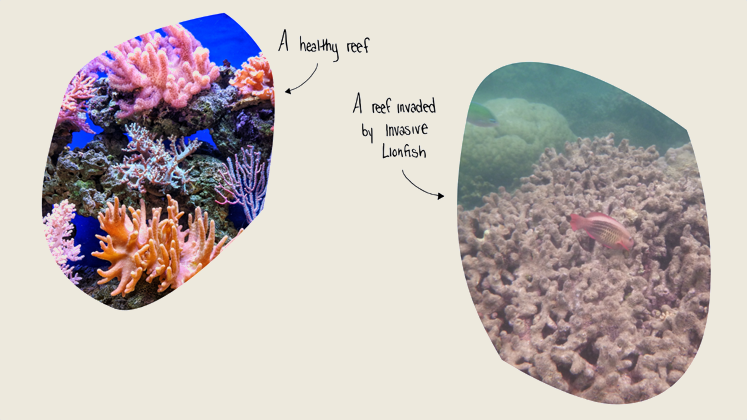

Fast forward 37 years and the invasive lionfish has completely taken over the Atlantic Ocean from Boston to Brazil to Barcelona. They’ve even infested the entire Mediterranean and everywhere they appear, they destroy coral reefs and the entire oceanic food chains.

With no natural predators in these waters and an unyielding appetite, a single invasive lionfish can efficiently kill up to 79 per cent of young native marine life within 5 weeks of entering a coral reef system – destroying entire food chains and thereby creating an ecological imbalance. Furthermore, invasive lionfish eat everything in their surrounding ecosystem – preying on more than 70 marine fish and invertebrate species.

Each lionfish that is removed can protect up to 70,000 native reef fish, allowing the reefs to rebuild from the destruction caused.

Princeton-trained Mechanical Engineer Aarav Chavda, an avid scuba diver and Founder of Inversa, has witnessed first-hand the gradual disappearance of colourful fish species, as well as the destruction of vibrant coral reefs. In a bid to halt the proliferation of this invasive species, he, together with a team of ecologically aware fellow scuba enthusiasts, birthed Inversa, which turns invasive lionfish into a new product i.e. fish leather.

Each lionfish that is removed can protect up to 70,000 native reef fish, allowing the reefs to rebuild from the destruction caused.

Lionfish skin is thin but because the fibre structure runs crossways, it is stronger and more resistant than many other types of leather.

“We believe doing good only works if you do it well. That’s why creating the best-in-class leather is our North Star. We run extensive third party testing to ensure that your lionfish leather is as robust as it is beautiful,” the company states.

Beyond sustainable, Inversa is regenerative

Inversa leathers are helping to solve environmental crisis. Beyond sustainable, the company labels itself as regenerative as it helps protect biodiversity by creating authentic leather that is more sustainable than traditional leather. This means that it does not require huge areas for grazing, contributing to soil degradation and the production of methane emissions.

“Sustainability has become an overused word that many of us feel we can no longer trust. We hate it and we know you do too. That’s why we make leather that is beyond sustainable. It is regenerative,” Inversa states.

Inversa leather is more sustainable than traditional leather as it does not require huge areas for grazing, contributing to soil degradation and the production of methane emissions.

Manufacturing and sourcing

The company sources its Lionfish from anywhere that the species is invasive. But currently, the majority of it comes specifically from all around the coast of Florida and from the coast of Mexico. Furthermore, despite their international sourcing, Inversa’s products are entirely processed and manufactured in the USA.

While the Lionfish leather is tanned and dyed by the American start-up, the raw material is sourced by local fishermen.

Inversa processes the fish hides by tanning them with drying agents and dyes them before selling the leather to partner companies to fashion into high-end products including sneakers, wallets, belts, handbags or even watch straps.

“We are happy to say that we do not use toxic Chrome VI. Instead, today, like 75%+ of leather in fashion today, we use Chrome III in our tanning process. However, we believe in pushing the boundaries of eco-sensitivity, and within 12 months, we will be shifting to bio-based tanning via Zeolite,” the company states.

Instead of hunting the lionfish itself, Inversa relies on educating and encouraging largely poor fishermen and women in often remote places to catch them.

On World Oceans Day, Inversa was recognised as one of the nine finalists in the Global Ocean Resilience Innovation Challenge (Oric). The company is proposing to set up well-equipped fishing cooperatives in Quintana Roo, Mexico, by underwriting the fishers’ risk with a ‘100% catch-to-cash guarantee’ for Lionfish. This would finance the purchase of equipment, then offer premium incentives and prompt payment for lionfish.

“We’re really sort of empowering the consumer and fashion by doing something for the planet – then we empower dive communities in the fishing cooperatives all throughout the Caribbean to do something for themselves,” Chavda told The Guardian.

Design and Development

Inversa leathers are engineered to stand up to automotive grade testing, for which, the company partners with the leading leather innovation lab.

The start-up is constantly increasing its range of colours and comes out with a new set of colours every season in line with that particular season’s Pantone shades. However, the company is also continuously creating custom colours for its brand partners as per their specific requirements.

Priced at US $ 35 per hide, Inversa’s MOQ for invasive lionfish hides is 3 hides. After placing an order, one can expect to receive a sample within 1-2 weeks. For full scale orders, the company creates a production timeline as part of their proposal because delivery depends on the size of the order and any custom colour development required.

Commercial viability

In just a short span of time since its inception, Inversa leather has already started showing commercial viability depicted in the company’s various partnerships with fashion and lifestyle brands.

The company collaborates with Italian footwear brand P448 to offer more sustainable shoes that can help protect biodiversity and restore a certain ecological balance in the world’s oceans and seas. For three seasons in a row, P448 has been committed to launching greener collections and its partnership with Inversa marks ‘the first time in fashion that a product goes beyond minimising environmental impact and focuses on regenerating damaged ecosystems.’

Inversa has also partnered with the Teton Leather Company – a custom leather manufacturer specialising in high-end exotic goods to create innovative eco-positive art. Teton has used Inversa leather across various product categories, including wallets, clutches, watch straps and more.