Hemp is a versatile plant cultivated for its seeds, fibre and flowers, making it a multi-purpose crop with applications in various industries. Its unique properties have created markets for a wide array of products, including textiles, clothing, ropes, home furnishings, industrial oils, cosmetics and even food and pharmaceuticals.

Furthermore, the diversity of hemp-derived products is so vast that it intersects with more markets and industries globally than any other crop, showcasing its significance in the modern economy.

In the field of botanical and regulatory classification, hemp is precisely defined as ‘a Cannabis sativa L. plant — or any part thereof — in which the concentration of tetrahydrocannabinol (THC) in the flowers and leaves of the inflorescence does not exceed the regulated maximum level established by relevant authorities’.

It is crucial to differentiate industrial hemp from marijuana, another variant of Cannabis sativa L. that is characterised by significantly elevated THC levels of up to 20 per cent.

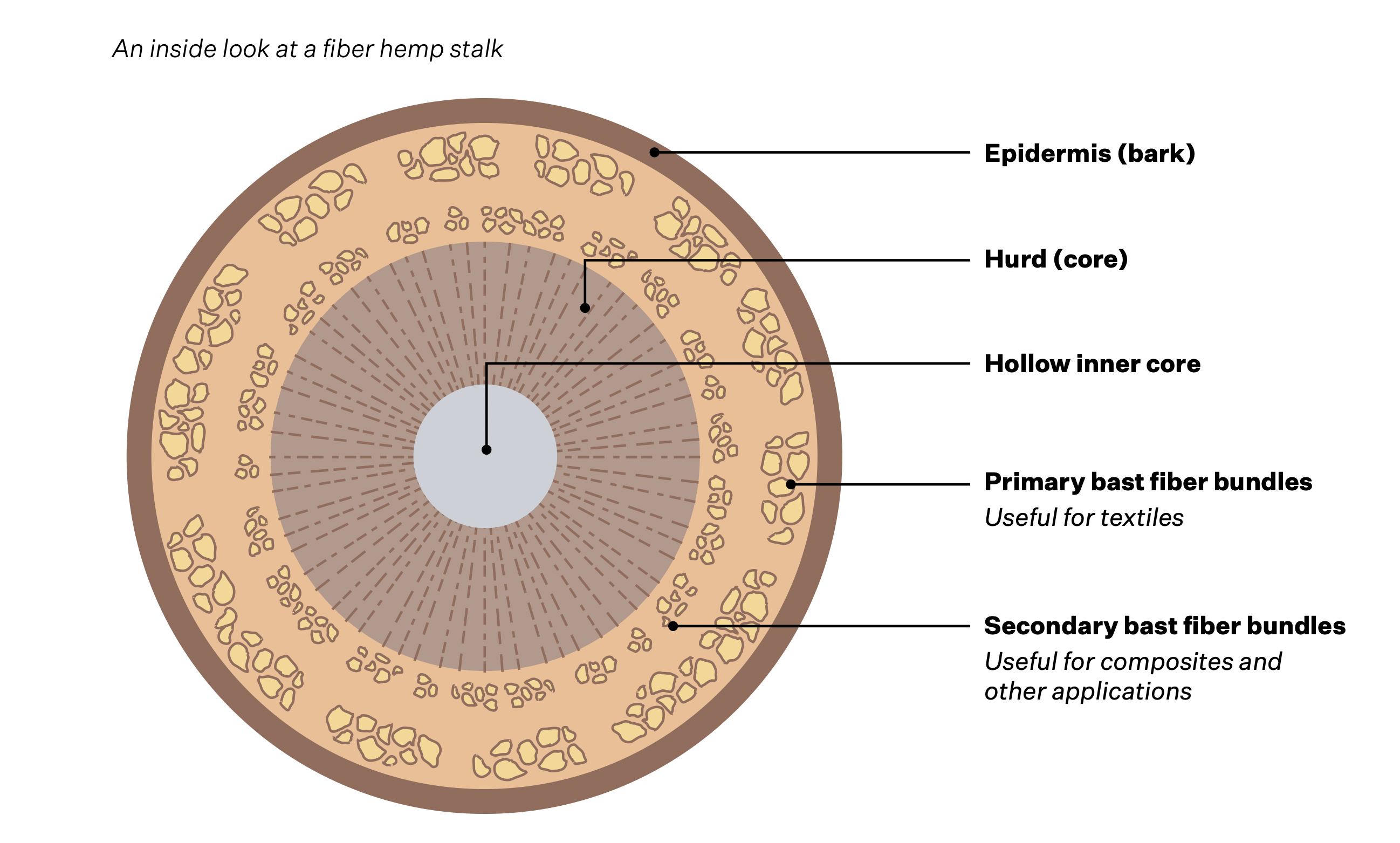

Within the Cannabaceae family, hemp serves as a bast fibre, a crucial component of its botanical structure. The fibre-producing section of the plant comprises strands that extend to the entire length of the plant, enveloping the ‘hurd’, which constitutes the woody core of the stem. These fibres are encased in a delicate ‘bark’ characterised by a thin, gummy varnish. The attachment of fibres to the air-filled, woody core is facilitated by pectin, while lignin functions as the binding agent, bundling the fibres along the stalk.

It is this intricate composition that highlights the versatile applications of hemp in various industrial and commercial sectors.

FROM WASTE TO WEALTH IN APPAREL AND BEYOND

Over the years, hemp fibres have evolved from being perceived as waste byproducts to becoming invaluable resources for a wide range of applications. Varied industries from apparel and textiles to paper, carpeting, construction, insulation materials, auto parts and composites now benefit from hemp’s versatility.

Previously relegated to uses like animal bedding, material inputs, papermaking and oil absorbents, hemp fibres have found diverse roles in the modern market.

In the textile sector, hemp has become a staple material in various products such as casual, formal and workwear apparel, as well as sheets, towels, shoes, tote bags, drapes and carpets. What sets hemp apart is its exceptional strength, durability, antimicrobial and UV-resistant properties, natural resistance to mold, mildew and rot and its ability to readily accept dyes. Moreover, hemp fibres soften with each wash without degradation and offer excellent breathability.

Although hemp can have a slightly rough texture and lack natural drapery, they are often blended with softer fibres like cotton, silk or wool, enhancing their usability in apparel. Pure hemp, akin to new linen, softens further with each wash and wear.

Additionally, the burgeoning nonwoven hemp sector has seen the incorporation of hemp fibres in feminine hygiene products and wipes, further expanding the range of applications for this versatile and sustainable material.

FIBRE HEMP PRODUCTION AROUND THE WORLD

‘Growing Hemp for the Future’ report by Textile Exchange, highlights that in 2021, approximately 21 countries cultivated fibre hemp, including Austria, Bulgaria, Chile, China, Czechia, France, Germany, Italy, Japan, Netherlands, Poland, Romania, Russia, Spain, Turkey, Ukraine and the United States, amongst others.

According to data from FAO, USDA and TURKSTAT, global fibre hemp production for that year was estimated at around 3,02,000 tonnes (6,65,000 lbs.) harvested from 79,000 hectares (196,000 acres) of land.

In the textile sector, hemp has become a staple material in various products such as casual, formal and workwear apparel, as well as sheets, towels, shoes, tote bags, drapes and carpets. What sets hemp apart is its exceptional strength, durability, antimicrobial and UV-resistant properties, natural resistance to mold, mildew and rot and its ability to readily accept dyes.

The United States has emerged as a notable producer of fibre hemp, with USDA records indicating a harvest from 5,138 hectares (12,690 acres), resulting in a yield of 15 million kilograms (33.2 million pounds) of fibre hemp in 2021. Similarly, data from TURKSTAT revealed a harvest of 21 tonnes (46,200 lbs) of fibre hemp in Turkey during the same year, indicating a growing global interest in fibre hemp cultivation.

Taking into account the available data from FAOSTAT, USDA and TURKSTAT, global fibre hemp production in 2021 is estimated to be around 3,02,000 tonnes (6,65,000 lbs.) harvested from 79,000 hectares (196,000 acres). It’s important to note that this estimate is based on incomplete data and excludes countries where fibre hemp production is occurring but data is unavailable. The figures highlight the growing significance of fibre hemp cultivation worldwide, with notable contributions from countries like the United States and Turkey, despite gaps in the data.

LEADING AND UP-AND-COMING FIBRE HEMP PRODUCING COUNTRIES AND REGIONS

In 2021, several countries stood out as significant fibre hemp producers based on data from reputable sources such as FAO and the USDA Department of Agriculture. Amongst these, prominent nations were China, France, North Korea (estimated figures), Poland and the United States.

HISTORIC LEGAL STATUS OF HEMP IN THE LEADING PRODUCTION REGIONS

The global production of hemp is gradually gaining acceptance, with an increasing number of countries permitting their farmers to cultivate this versatile crop. In France, while hemp was never officially prohibited, its production significantly declined during the 20th century due to the widespread use of imported cotton and synthetic fibres.

Then in 1990, France took a significant step by authorising the cultivation, import, export and utilisation of hemp, with the condition that only the fibres and seeds would be utilised; the sale of flowers and leaves remained banned until late 2022.

China’s prominent position in the hemp production and processing sector is rooted in its longstanding tradition of hemp cultivation. This dominance can be attributed, in part, to the fact that hemp was banned in China for only 25 years, in contrast to over 80 years in the United States.

Textile Exchange’s report finds that historical legislations, such as the Marijuana Tax Act of 1937, effectively halted hemp farming in the US, although it didn’t officially declare it illegal. Briefly revived during World War II for rope production, hemp faced further restrictions under the Controlled Substances Act of 1970, requiring a DEA permit for cultivation. However, by that time, industrial hemp cultivation had ceased in the US.

The 2018 Farm Bill marked a turning point, finally permitting hemp production in the country. These prohibitions and restrictions severely impeded research into suitable hemp varieties and production methods for different regions, while also hindering the development and maintenance of essential machinery, from decortication to finer processing stages.

That being said, much of the necessary research and development is only now gaining momentum, despite the industry’s anticipation for these issues to have been resolved earlier.

HEMP PRODUCTION STANDARDS

Companies emphasising responsible practices and sustainable production find enhanced protection when they participate in independent verification programs. Programs including Organic, Regenerative Organic Certified, Preferred by Nature Framework and the ISCC, cover vital aspects of Textile Exchange‘s Climate+ strategy and address critical factors such as pesticide and fertiliser use, irrigation/water management, greenhouse gas reduction, soil health, biodiversity, land use changes and human rights.

Additionally, these programs prohibit the use of pesticides classified as extremely or highly hazardous by the World Health Organization (WHO), as well as those banned by international conventions. By adhering to these standards, companies not only promote environmental and human well-being but also bolster their credibility by demonstrating their commitment to sustainable and ethical practices.

HEMP TEXTILE PROCESSING AND MANUFACTURING

The journey from hemp plant to finished textiles involves numerous intricate stages of production and post-harvest processing.

For apparel and home textiles:

Retting: Separation of fibres from the stem through soaking and microbial action

Decorticating: Removal of the outer bark to reveal the fibres

Scutching (for long fibres): Beating and scraping to further refine the fibres

Degumming: Removal of natural gums and impurities from the fibres

Cottonising/Mechanical Softening: Process to make fibres more like cotton, if not degummed

Hackling: Combing to align the fibres and remove short or damaged ones

Carding: Separation and alignment of fibres for spinning

Drawing: Further stretching and thinning of fibres

Roving: Twisted and drawn fibres ready for spinning

Spinning: Twisting fibres into yarns

Knitting/Weaving: Creating fabric from yarns through knitting (for textiles like sweaters) or weaving (for fabrics like linen)

Finishing: Processes including bleaching, dyeing and other treatments for desired appearance and texture

Cutting and Sewing: Fabric cut into patterns and sewn into final products

For non-wovens:

Retting: Separation of fibres from the stem through soaking and microbial action

Decortication: Removal of the outer bark to reveal the fibres

Cleaning: Removing impurities and foreign matter from the fibres

Carding: Separation and alignment of fibres

Nonwoven Fabric Production: Creating fabric directly from fibres without the need for spinning or weaving, often through processes like bonding or felting

Each step in this intricate process plays a huge role in the quality and characteristics of the final hemp textile product, whether it’s for apparel, home textiles, or non-woven applications.

In March 2022, Textile Exchange conducted a preliminary internal review focusing on companies engaged in hemp production and processing. The review specifically targeted entities certified by two prominent voluntary standards in the organic textile market: Textile Exchange’s Organic Content Standard (OCS) and Global Standard GmbH’s Global Organic Textile Standard (GOTS).

While these standards differ in scope – GOTS emphasises both social and environmental responsibility in processing stages, whereas OCS primarily verifies organic content – both ensure a comprehensive chain of custody from the field to the final product.

They recognise fibres originating from farms undergoing organic certification or in the conversion process and identify the retting stage as the initial processing phase.

Companies often opt for OCS when they intend to use less than 70 per cent minimum organic content required by GOTS, as OCS permits organic content claims ranging from 5 per cent -100 per cent. Additionally, conventional hemp is accepted in OCS alongside organic fibres. In contrast, GOTS certification allows conventional hemp only if it is not blended with organic hemp and comprises less than 30 per cent of the fibre content in certified products.

Although hemp can have a slightly rough texture and lack natural drapery, they are often blended with softer fibres like cotton, silk or wool, enhancing their usability in apparel. Pure hemp, akin to new linen, softens further with each wash and wear.

Key Takeaways:

- Certified companies encompass all post-farm hemp production stages, from decortication to retailing, with many businesses engaging in multiple processing phases.

- Hemp finds application in various products, including yarns, fabrics, home textiles and apparel for babies, children, men and women.

- Among OCS- and GOTS-certified companies involved in hemp, China, India, Portugal and Turkey emerge as the key regions for hemp processing and manufacturing. These countries play a pivotal role in the production and distribution of high-quality hemp-based textiles and products adhering to organic and sustainable standards.

THE WAY FORWARD

The future of hemp production stands at a vital juncture. Worldwide, restrictions on this once-stigmatised crop are lifting, in tandem with a growing awareness of the challenges linked to input-intensive agriculture. While there is immense excitement about hemp’s sustainability potential, it is crucial to recognise that the solution lies not just in growing, sourcing or wearing hemp, but also in how it is cultivated.

Since the availability of conventional pesticides authorised for global hemp production is limited, the industry has a unique opportunity to pioneer production practices that harmonise with nature, fostering measurable benefits for this revitalised fibre crop.

At the same time, it is imperative for governments, brands and farmers to collaborate and establish systems that yield high-quality raw materials using low-toxicity inputs, thereby maximising environmental benefits. This collaborative effort is required to ensure the sustainable future of hemp production, setting a precedent for environmentally conscious agriculture practices globally.

Hemp holds immense sustainability potential, offering a unique opportunity for the industry to build its production system from the ground up. Through collaborative efforts and by drawing on lessons from the past, one can harness the holistic benefits of hemp to align with our climate and environmental goals.

By embracing innovative, eco-friendly practices, the hemp industry can serve as a model for sustainable agriculture and contribute significantly to a greener, more environmentally responsible future.