Covestro, the polymer material manufacturer, has come up with a new method of obtaining elastic fibres through the partial use of carbon dioxide instead of the crude oils.

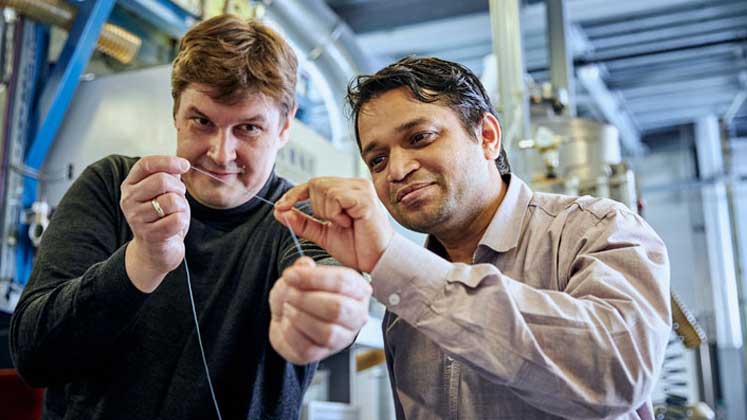

The innovation was done in collaboration with the Institute of Textile Technology at RWTH Aachen University.

While substantiating on the innovation, Professor Thomas Gries, Director, Institute of Textile Technology at RWTH Aachen University, averred “The CO2-based material could be a sustainable alternative to conventional elastic fibres in the near future. With Covestrol, we can jointly drive the establishment of a new raw material base for the textiles industry.”

These fibres made using CO2-based thermoplastic polyurethane (TPU) are manufactured using the melt spinning techniques, in which the TPU is melted and pressed into fine threads before processing into yarn.

This eliminates the use of any harmful solvent during the process and makes these fibres a lot more sustainable, thereby reducing the carbon footprint when compared to the traditional elastic fibres.

Also, the fibres obtained are high performing fibres with an improved stretched and tear-proof properties.

“That’s a further, highly promising approach to enable ever broader use of carbon dioxide as an alternative raw material in the chemical industry and expand the raw materials’ base. Our goal is to use CO2 in more and more applications in a circular economy process and save crude oil,” said Dr. Markus Steilemann, CEO, Covestro.

Furthermore, the German Federal Ministry of Education and Research (BMBF) which is keen to see the fibre enter the market will fund the future prospects of the project which is to scale Covestro’s elastic fibre via the CO2Tex. Moreover, these CO2-based fibres have been tested by the companies from the textile and medical engineering sector in socks, compression tubes and tapes.