How can the industry be educated about Lean manufacturing? The first step of Lean implementation is to make people understand what “Lean” is as it cannot be achieved by merely stating theoretical principles. It has to be explained with the aid of simulations and examples, which can be imparted with the aid of a managerial kit.

A “Lean Toolkit” has been developed by Gopal Bharti and Shan Abdur Rahman, both former students of Department of Fashion Technology NIFT, Delhi under the guidance of Dr. V. Senthil Kumar, Associate Professor, NIFT and industry mentor Roger Thomas, during their graduation research project. The following pages outline few areas how Lean Toolkit can be used to bring awareness among people and make them understand the complex systems.

The world is increasingly getting competitive. The changing international market dynamics have forced various companies to adapt to Lean Manufacturing rather than stick with traditional manufacturing. Companies are fast adopting Lean philosophy due to various factors such as pressure from customers, competitors, and shareholders to improve performance. There is a growing recognition that supporting and scaling Lean implementations is prerequisite for customer responsive market.So what is Lean?

“Lean” is a philosophy that pursues to identify and eliminate waste and bring in “perfectness”. With a goal to create maximum value, non-value adding activities are eliminated through a process of continuous improvement. Lean is not just a production methodology, nor is it just a mere strategy but it is a philosophy which needs to be embedded in an organization. It has to trickle down from the top management to the bottom-most level. Everyone in the factory should be educated and made aware how they can benefit from “Lean”.

Lean Toolkit

It is ultimately the managers who will get the work done and thus they have to understand the principles. It is important that they believe in the philosophy before implementing “Lean”. It has to be embedded in their mindset and this necessitates the importance of a Lean Toolkit for the management.

The Lean Toolkit comprises of Lean booklet, presentations, games and simulations and case studies. This Lean Toolkit can be used to hold seminars or workshops for creating management awareness about Lean. This article will illustrate how the games and simulations achieve the Lean Objectives. The games can be played with participants to demonstrate Lean Principles.

GAME 1. PICK THE CRYSTAL BALLS

[bleft]With the application of 5S principles – Sort, Set, Shine, Standardize and Sustain, the work gets smoother, easier and requires lesser time. Similarly, the efficiency and productivity of doing any subsequent work increases significantly[/bleft]

Objective: To make the participants understand the importance of 5S principle “Sort”.

In this demonstration one person is selected at random to play the game.

Scenario 1: A large bowl is placed containing large numbers of water crystal balls of various colours. The player selected to play the game is

given a test tube having specific sequence crystal balls placed in it. The player is asked to fill an empty test tube with coloured balls in similar sequence. The time taken by the player is recorded by the stopwatch.

Result: While playing the game it is found that since various coloured balls are mixed and kept in the same bowl it becomes even more difficult to choose the right coloured ball as per sequence in the test tube.

Scenario 2: Now three bowls containing distinct coloured balls are placed on the table. The same player is asked to repeat the procedure of filling an empty test tube with the same sequence presented to him earlier in the exercise. The time taken by the player is recorded again by the stopwatch.

Result: While playing the game in second scenario it is found that the difficulty in searching the right coloured ball as per the sequence in the test tube is eliminated since various coloured balls are segregated and kept in different bowls.

Conclusion: If results of scenario 1 and scenario 2 are seen, we find that it is easier to fill the test tube when different coloured balls are segregated into different bowls. The results of the demonstration highlights the importance of 5S principle “Sort” are discussed.

GAME 2. INFORMATION FLOW AND EFFECTIVE COMMUNICATION

Objective: To make the participants understand the importance of correct information flow and proper communication channel.

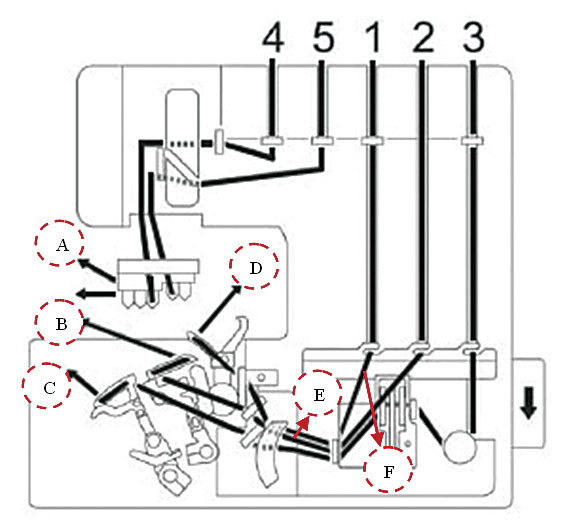

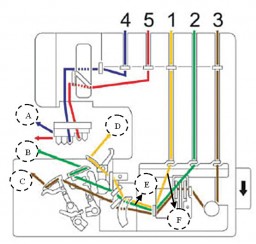

Scenario 1: If a person is asked to label the alphabets in circles with their corresponding thread number, it would require some effort and concentration to figure out the corresponding thread numbers for each alphabet.

Result: Since all the threads are represented in the same colour, i.e. black, it may be difficult to differentiate one thread from the other.

Scenario 2: Similarly, now if a person is asked to label the alphabet in circles with their corresponding thread number for a coloured diagram, the work would get much easier.

Result: Since all the threads are represented in different colours, visually it is easier to identify and differentiate threads.

Conclusion: It is very important that vital information is communicated to the people in a most simple method so that problems do not occur at first place. In the above example the quality of stitch solely depends on the correct threading of the machine.

GAME 3. TIME MACHINE

Objective: To demonstrate the importance of 5S principles “Sort”, “Set”, “Shine” and “Standardize”.

Objective: To demonstrate the importance of 5S principles “Sort”, “Set”, “Shine” and “Standardize”.

This game is played in 5 stages and at each stage the participants are provided with different sheets. The sheets contain clocks displaying various times between 2 o’clock and 7 o’clock. The first sheet depicts state of chaos prevalent in most of the companies, and all the rest 4 sheets that are used to demonstrate the 5S principles – Sort, Set, Shine and Standardize – contain the same number of clocks. They are different in appearance because they are arranged differently to demonstrate importance of each principle.

At each stage when the participant is provided with a different sheet, he/she is required to arrange time displayed by clocks between 2 o’clock and 7 o’clock in ascending order in stipulated period of time written on the sheet.

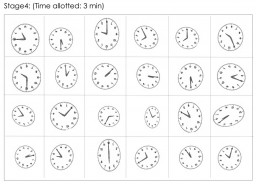

Stage1: (Time allotted: 6 min.)

The first sheet demonstrates the common scenario observed in most of the garment manufacturing companies. In this sheet the clocks are randomly arranged in a disoriented and disorganized manner depicting haphazard and unsystematic workflow.

Result : When the players are instructed to write all the times displayed by clocks between 2 o’clock and 7 o’clock in ascending order on the sheet, it seems a mammoth task for the participants to write down the time because not only the clocks are arranged randomly, but also the orientation of the clocks are skewed.

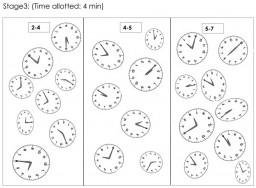

Stage 2: (Time allotted: 5 min.)

The second sheet demonstrates how the 5S principle “Sort” can help to improve chaotic and unsystematic conditions in the garment manufacturing companies. In this sheet the clocks that are only displaying time between 2 o’clock and 7 o’clock are sorted and rest of the irrelevant clocks, which were present in the earlier sheet are eliminated.

Result : When the players are instructed to write all the times displayed by clocks between 2 o’clock and 7 o’clock in ascending order on the sheet, it is observed that after sorting the sheet is less cluttered and it gets little easier but still difficult to manage the whole exercise because the clocks are still randomly arranged and skewed.

Stage 3: (Time allotted: 4 min.)

differential timings

The third sheet demonstrates, how following the 5S principle “Set in order” after the process of sorting has been carried out can help to improve conditions and productivity in garment industry. In this third sheet the same number of clocks that were present in the earlier sheet is categorized in three different time zones such as 2-4 o’clock, 4-5 o’clock and 5-7 o’clock.

Result: When the players are instructed to write all the times displayed by clocks between 2 o’clock and 7 o’clock in ascending order on the sheet, the participants find it easier to write down the time than the previous instances because segregation of clocks in zones gives the participant the fair idea of timings shown in the clocks.

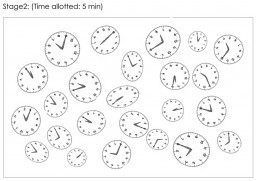

Stage 4: (Time allotted: 3 min.)

The fourth sheet demonstrates how the 5S principle “Shine” helps to improve efficiency and productivity in garment industry. In this sheet the same numbers of clocks are present as in earlier sheets and arranged in clearly demarcated cubicles in ascending order. The only thing that is not right about this arrangement is that they are still skewed in orientation.

Result : When the players are instructed to write all the times displayed by clocks between 2 o’clock and 7 o’clock in ascending order on the sheet, it gets much easier because the clocks are already arranged in ascending order they just need to get the orientation of the clock right and write down the correct time.

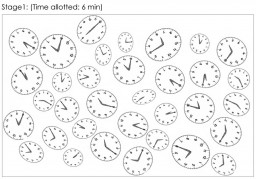

Stage 5: (Time allotted: 2 min.)

The fifth sheet demonstrates how the 5S principle “Standardise” helps to improve work efficiency and productivity. In this sheet the same number of clocks as present in earlier sheets is arranged in clearly demarcated cubicles in ascending order and proper orientation. It demonstrates the ideal situation that should exist in garment manufacturing company.

Result : When the players are instructed to write all the times displayed by clocks between 2 o’clock and 7 o’clock in ascending order on the sheet, it is just a cakewalk because the clocks are already arranged in ascending order and are in proper orientation. The task is just to note down the timings as quickly as possible.

Conclusion : The level of ease in doing each sheet with subsequently less time required to do each sheet is discussed and it can be observed that with application of 5S principles, the work gets easier. Similarly, the efficiency and productivity of doing any subsequent work increases significantly.

GAME 4. POKA YOKE

Objective:

To make the participants understand the importance of Poka Yoke – Error Proofing.

In this exercise all the participants are required to take active part in the discussion. The discussion is about simple applications of Poka Yoke in our day-to-day lives. The discussion on how few devices that are used in our everyday life, are designed in such a way that prevents any occurrence of error.

“If we have door X with a handle and ‘push’ written on it, still people will often make a mistake of pulling it by handle (as you are allowing to ‘pull’ by handle). Please note ‘push’ written does not help as your mechanism (having a handle) allow people to make mistake. Instead if we have door Y with a flat plate (even if ‘push’ is not written on it) and no handle, then people will have no option than to ‘push’ it. Thus for a push door an error proofing option is not to have any handle, rather a flat plate (to indicate where to push) is sufficient”.

Discussion : Application of Poka yoke in garment industry

The debate is on how this principle of error proofing can be used in garment industry? Chances are that asymmetric ready pattern templates which look similar when used can sometimes result in wrong marking if a pattern is flipped upside down by mistake. As templates are having same colour in both sides, the flipping of pattern goes unnoticed by the concerned person. If templates can be coloured differently in the face and back side then very easily any advertent flipping of template can be noticed and thus the operation is error proofed.

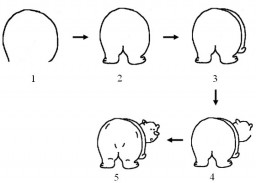

GAME 5. ‘M’ EASY TO DRAW

Objective: To make the players understand the importance of “Standardization of work”.

In this demonstration all the persons attending the seminar can participate. Each participant is provided with a sheet in which there is a figure that is to be drawn as per instruction.

Scenario1: Each participant is asked to draw the given figure (as shown here) in a certain time period.

Result : The participants who are especially not good at sketching and drawing find it little hard to begin drawing or replicate the figure.

Scenario2: Now each participant is provided with step-by-step diagram to draw that same figure as given below:

Result: When clear steps of drawing the same figures are given, the participants find it relatively easier to draw and replicate the figure. Initial hitch of how to begin; among participants who are not so good at is also lost in second scenario.

Conclusion : When the observations are discussed, the emphasis is laid on the importance of Standard Operating Procedure. This is critical to accomplishing very little or no variation in work and ensuring high quality of products. The discussion should focus on better and effective standard operating procedures to enhance our quality levels.

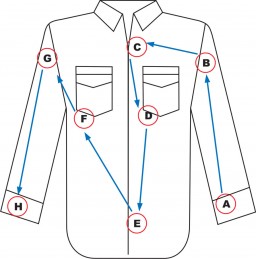

Examples of this principle can be sighted from garment inspection

While checking the quality of the garment different inspectors or end-line checkers start from different points and usually follow the path in which they see a defect first and then they move to the next area. Since these checkers and inspectors are not given standardized instructions or formal training in inspection they do not follow a standardized method of checking.

For example while inspecting a shirt, someone starts from pocket (A) and goes right up to reach the right shoulder (E), as shown in figure 1 above, while the other goes from top to bottom and so on. This non-standardized method will result in variability resulting in differential timings.

A standard inspection procedure may help in overcoming the shortcomings in the present garment inspection process. If the end-line checkers and quality inspectors are provided with definite instructions and arrow diagrams as shown in figure 2 above, the inspection process becomes standardized thus there is repeatability of achieving the target. The diagram follows a definite pattern of inspection which ensures that no part is left unchecked.