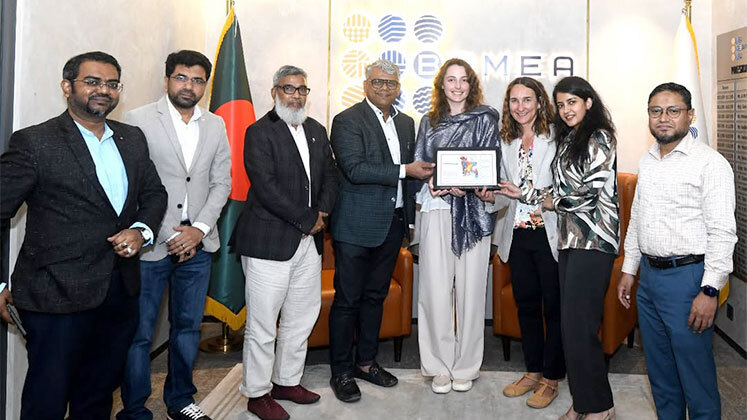

A high-level international delegation representing the Sustainable Manufacturing and Environmental Pollution (SMEP) Programme, Solidaridad Network Asia, QStone Capital and Kingsley visited the BGMEA to explore strategic pathways for strengthening wastewater reuse across Bangladesh’s ready-made garment (RMG) sector.

During the meeting, BGMEA Directors Nafis Ud Doula and Mohammed Sohel exchanged insights with the delegation on how scalable, investment-ready solutions could accelerate the industry’s shift towards more efficient and environmentally responsible wet-processing operations. Discussions focused on expanding wastewater reuse capacity and reducing the sector’s water footprint—an area that has drawn increasing global attention amid rising sustainability expectations.

The SMEP project has introduced a modular, movable Zero Liquid Discharge (ZLD) technology specifically designed for textile wet-processing units. According to SMEP, the system can reuse up to 80% of wastewater, reducing freshwater dependence and significantly cutting pollution levels. SMEP representatives said the model is well suited to factories with space limitations, fluctuating production loads or high compliance costs, enabling broader adoption beyond large facilities.

In recent years, Bangladesh’s textile industry has increased investment in green technologies, water-efficient dyeing and resource recovery. Data from the International Finance Corporation (IFC) suggests that improvements in wastewater treatment, when coupled with recycling and process optimisation, can reduce water use by 15–20% in the short term. The delegation noted that modular ZLD provides an additional opportunity for factories to go beyond conventional effluent treatment performance and integrate circular water systems.

The meeting also explored potential avenues for blended finance, technical assistance and industry-wide demonstration initiatives. Representatives from Solidaridad stated that collaborative interventions would be essential in reducing barriers for medium-scale factories that often struggle with the high capital requirements of traditional ZLD systems. Experts from QStone Capital added that innovative financing mechanisms would be critical for scaling adoption across the sector.

BGMEA welcomed the initiative, observing that responsible water management is becoming increasingly central to global sourcing priorities. The association stressed that with international buyers placing greater emphasis on environmental compliance, technologies such as modular ZLD can help strengthen Bangladesh’s competitiveness while safeguarding natural ecosystems.

The meeting concluded with a shared commitment to continue dialogue and explore pilot opportunities that could later be scaled industry-wide. If successfully implemented, the modular ZLD model is expected to set a new benchmark for wastewater reuse in Bangladesh’s textile value chain, reinforcing the country’s position as a global leader in sustainable manufacturing.