Out of sight, out of mind – That’s often the case with little components like trims and accessories when we talk about sustainability in fashion. While conversations revolve around fabric, yarn, fibre, dyeing and the final garment, zippers, interlinings, threads, buttons, tags, labels, twill tapes, laces and others are quietly overlooked despite their essential role.

But a strong shift is underway.

Today, trims and accessories are undergoing a quiet yet powerful makeover driven by increasingly eco-conscious consumers, tightening global regulations and strong market demand.

Interlinings, for example, are now being made from recycled polyester and organic cotton blends. These innovations are finding favour with technical, sportswear and even fast-fashion brands that are being held to higher compliance and transparency standards.

Zippers made from recycled yarns and metals are replacing conventional versions. Buttons, snap fasteners and buckles are being produced using recyclable or low-impact materials backed by certifications like GRS, Oeko-Tex and ISO 14001.

Even threads and embroidery are being reimagined, with biodegradable fibres made from FSC-certified wood pulp, recycled PET bottles and closed-loop processes replacing conventional synthetics.

Similarly, labels, tapes, tags, laces, packaging components and hang loops are being reengineered to meet international standards for toxicity, ethical sourcing, recyclability and material traceability.

We spoke to leaders in trims and accessories to explore how sustainability is no longer optional; it’s becoming the industry standard.

| 25%

Freudenberg aims to garner around 25% of its apparel sales from sustainable products by 2025. Its offerings include apparel interlinings, tapes, waddings, canvas and preform materials, linings and Comfortemp thermal insulations. |

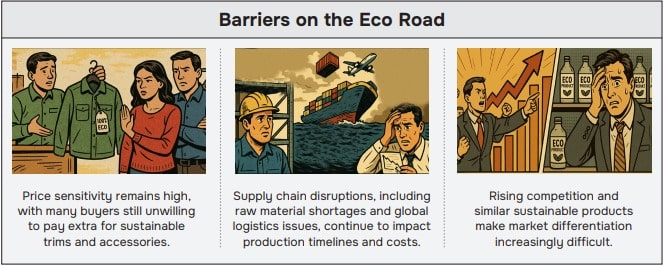

Demand Soars for Sustainable Products

According to Custom Market Insights, the global sustainable fashion market is experiencing good growth, with projections indicating it will reach US $ 33.1 billion by 2033, up from US $ 8.1 billion in 2024. No wonder, experts across the board report a strong rise in demand for eco-friendly options across every product category.

“Performance-focused brands are prioritising eco-friendly solutions. Our RCY series with recycled polyester interlinings, has been especially successful with them.”

| “At our Ranipet plant, the company has advanced this process by introducing an automated powder dispensing system with suction and dosing accuracy down to 1/1000th of a gram, ensuring precise colour matching and high reproducibility even if the same shade is required for 25 years.” Sanjeev Kumar Grewal, Regional Business Director, AMANN Group |

| “We are seeing an exponential increase in the demand for sustainable products and production methods. Our Sustainable 360 collection continues to grow season after season and today includes more than 300 products made exclusively from eco-responsible materials.” Gianluca Tanzi, CEO and Chairman, Chargeurs PCC |

| “Performance-focused brands are prioritising eco-friendly solutions. Our RCY series with recycled polyester interlinings, has been especially successful with them.” T. Boopalan, Director, Freudenberg Performance Materials India Pvt. Ltd. |

Boopalan, Director, Freudenberg Performance Materials India Pvt. Ltd.

“Performance-focused brands, from sportswear to outdoor apparel, are prioritising eco-friendly solutions. Our RCY series with recycled polyester interlinings, has been especially successful with them. Even fast-fashion brands, once driven purely by speed and trends, are now embracing sustainability as a core part of their product strategy,” said T. Boopalan, Director, Freudenberg Performance Materials India Pvt. Ltd., which offers apparel interlinings, tapes, waddings, canvas and preform materials, linings and Comfortemp thermal insulations.

The company aims to garner around 25 per cent of its apparel sales from sustainable products by 2025. Boopalan emphasised the industry’s push for transparency and traceability, adding, “We work closely with platforms and standards such as Higg, Be Hive, TrusTrace, IPE, Inspectorio, GRS/TC and BCI.”

Similarly, Gianluca Tanzi, CEO and Chairman, Chargeurs PCC, a manufacturer of fabrics and interlinings for leading fashion houses and sports brands, stated, “We are seeing an exponential increase in the demand for sustainable products and production methods. Our Sustainable 360 collection continues to grow season after season and today includes more than 300 products made exclusively from eco-responsible materials such as BCI cotton, GRS-certified recycled polyester, hemp and more.”

Gianluca also pointed out that emerging regulations such as Digital Product Passports (DPP), which ensure comprehensive data sharing across the supply chain, are driving significant industry transformation.

The momentum isn’t limited to global leaders. Emerging players are also embracing sustainability.

“Customers, especially in the organised sector, are increasingly asking for sustainable products. Certifications like GRS and BCI are now standard and ISO 14000 is commonly required for environmental compliance,” said Manish L. Rupani, Executive Director, Talcofuse.

The company provides a wide portfolio of materials including 100 per cent cotton woven and blended interlinings, cotton fabrics, PC fabrics and 100 cent polyester fabrics for both domestic brands and exporters.

HOW ACCESSORIES ARE REDEFINING FASHION

Fashion trims and accessories are no longer limited to just being functional add-ons but have evolved to become expressive, design-defining elements that inject personality, innovation and character into garments. Today, they’re central to storytelling, utility and identity, playing a transformative role in how garments are conceptualised and worn.

- At Paris Fashion Week, Hermès’ Spring/Summer 2025 collection showcased zippers that appeared to be more than closures – they served as visual punctuation boldly running through trousers and bodysuits. These zips lended an edge of modernity and movement to the garments, highlighting how structural elements are now being used as central points of interest to highlight silhouette and style.

- Meanwhile, Zoomer’s F/W ’25 collection dismantled conventional dressing codes by putting a new spin on how garments are worn. The collection showed jackets styled backward, with zippers climbing all the way up the spine – a radical design choice that challenged perceptions of symmetry and function.

- At New York Fashion Week, Sandy Liang offered a nostalgic yet forward-thinking take on fleecewear featuring zip-up vests rendered in Polly Pocket pink, paired with matching quarter-zips and coordinated miniskirts that merged playful femininity with utilitarian details. Long zip-up tunic fleeces for day-to-night wear further underscored the transitional clothing trend that is witnessing a resigning demand across categories.

- Zippers also made a strong case for sculptural fashion at Alexander McQueen, where spiral zip detailing was spotted on ivory knit dresses and single-breasted blazers – both blurring the lines between function and form. Balmain also introduced zippers in unconventional placements on cuffs, pockets and at angles, transforming them into directional design tools.

Bottega Veneta, on the other hand, offered a witty yet refined approach by using magnetic snap closures that doubled up as jewellery pieces, highlighting the evolving intersection of function and ornamentation. Accessories, here, are not just practical but they convert into wearable art.

- Buttons and fasteners are also being reimagined as artistic and symbolic details. Actor Jessica Alba was spotted at Paris Fashion Week in a Gabriela Hearst floor-length coat adorned with two vulva-shaped white buttons — a detail that has now become a signature in Hearst’s collections.

- Dubai Fashion Week S/S ’25 saw Buttonscarves showcase their oversized, iconic bags like the Nina, Mindy and Beverly, each punctuated with buttons as bold focal points. This design direction also signals the shift towards oversized detailing and accessories as statement pieces.

- The same evolution continues in the materials realm with the domain witnessing an increased preference for premium, conscious materials such as horn, recycled resin and brass, reflecting the industry’s broader shift towards sustainable luxury. Matte textures, laser-etched finishes and hidden fasteners that are sewn into the fabric and melt seamlessly into garments highlight a growing appreciation for subtle, elevated minimalism among consumers.

- Labels, too, are having a moment, peeking out from beneath collars, no longer wanting to be hidden inside. Brands like Off-White, Diesel and Marine Serre are placing labels front and centre on hems, backs and sleeves, transforming logos and tags into intentional graphic statements that emerge as standout features on garments. From embroidered patches on the back to silicone logo tags on hems and woven labels on sleeves, these details made a clear visual statement while playing into the ongoing trend of visible branding with a twist.

- Even traditionally unseen elements are being upgraded with Interlinings coming into the spotlight, especially in the menswear and tailored garments categories. Designers such as Zegna and Givenchy are using breathable fusibles, memory foam and stretch-support systems, reinforcing a dual focus on shape and comfort.

- As intricate detailing becomes vital to a garment’s identity, lace remains a key showstopper. Case in point: Dua Lipa’s black lace catsuit from Valentino’s Spring/Summer 2025 collection. The sheer floral lace, flowing from a high neckline to a pointed toe, showcased how traditional craftsmanship continues to hold space in wardrobes of the future – striking a balance between delicate details and boldness.

- From fasteners that challenge traditional silhouettes to interlinings that are giving a new meaning to luxury comfort, accessories are not just finishing touches — they are the story. The future of fashion is being boldly dictated by the details and it’s clear that the smallest components are shaping the biggest shifts.

Though threads typically make up just 1-2 per cent of a garment’s cost, they too are becoming part of the sustainability conversation.

Akshay Kumar, Director-Sales, Madeira, a German-based manufacturer of premium embroidery threads, shared, “While brands are pushing for sustainability, only a few exporters are currently demanding certifications for threads.”

Highlighting their eco-friendly offerings, he mentioned Sense Green, an embroidery thread made with TENCEL™ Lyocell fibres, derived from FSC-certified wood and produced through a closed-loop process.

He also introduced Polyneon Green, a premium embroidery thread developed by recycling post-consumer plastic.

Ankit Jain, MD, Neelam Threads, added, “We’ve worked with exporters for over 30 years and many now require sustainability certifications—especially those catering to European and US markets. While smaller exporters may be more flexible, most demand certifications like FSC, GRS, Oeko-Tex and GOTS to meet buyer compliance and boost product value.”

With an annual production capacity of 700 tonnes, Neelam Threads supplies a wide range of clients including high-end fashion designers, exporters, home décor brands, boutique labels and small-scale artisanal designers using hand embroidery.

Buttons and zippers are also getting a green upgrade.

“Brands today are highly discerning and sustainability certifications are often a prerequisite,” said Sweta Saraf, Director, D&G Button Products (India) Pvt. Ltd., adding, “At D&G, we proudly adhere to international benchmarks, including ISO 9000 and Oeko-Tex 100.”

With a global presence supported by strategic partnerships such as that with D&G China, the company exports to over 50 countries, catering to both Indian fashion retailers and international brands. Its product portfolio includes buttons, rivets, snap fasteners, eyelets, buckles, metal plates and more.

| US $ 33.1 B

According to Custom Market Insights, the global sustainable fashion market is expected to reach this target by 2033. |

Likewise, YKK, the world’s largest manufacturer of zippers, not only produces zippers made from recycled materials but also offers sustainable options made from organic cotton and TENCEL™ fibres.

Closer home, Indian manufacturers are also witnessing this shift in demand.

“We’ve seen a 30 per cent year-on-year rise in orders for our Ayka Zippers, which are made using sustainable materials and eco-conscious processes,” shared Aabhas Arora, MD, Ayka Zipper. The company manufactures a wide variety of nylon, metal, plastic, invisible zippers and sewing threads, serving both domestic and international markets across Europe, the US and Asia.

He added that brands ask for certifications such GOTS, GRS, Oeko-Tex® Standard 100, ISO 14001:2015 and ISO 45001:2018.

Labels are going green too. Piyush Jain, Director, Sharman Udyog, a manufacturer of woven and printed labels, hang-tags, tapes, badges, heat transfers, tag seals and packaging, shared, “Demand for sustainable trims has grown by 40 per cent in the last three years. One major Indian apparel brand recently shifted 100 per cent of its tag orders to our plastic-free option, contributing to a 10 per cent revenue boost in our sustainable product line.”

He said Sharman Udyog meets certifications like Oeko-Tex® STANDARD 100, Oeko-Tex® RECYCLED, GRS, Sedex SMETA (Sedex Members Ethical Trade Audit), GOTS and ISO 14001. Around 80 per cent of their export clients require these certifications and 40 per cent of domestic brands now prioritise Sedex and Oeko- Tex® for supply chain compliance.

| “Customers, especially in the organised sector, are increasingly asking for sustainable products. Certifications like GRS and BCI are now standard and ISO 14000 is commonly required for environmental compliance.” Manish L. Rupani, Executive Director, Talcofuse |

| “We are developing advanced threads such as sensory threads that respond to touch or environmental changes; conductive threads used in military uniforms and gear; and forensic threads that are tamper-proof and used in high-security applications like passports. Arun Mishra, MD, AMANN Group |

| “Brands today are highly discerning and sustainability certifications are often a prerequisite. At D&G, we proudly adhere to international benchmarks, including ISO 9000 and Oeko-Tex 100.” Sweta Saraf, Director, D&G Button Products (India) Pvt. Ltd. |

Manufacturing Gets a Sustainable Makeover

The industry is also going through a big shake-up to make its production process green.

For instance, T. Boopalan mentioned that Freudenberg’s House of Sustainability is made up of four elements — Certifications and Regulations, Raw Materials, Technology and Carbon Footprint — and offers over 500 sustainable solutions that help customers meet their sustainability goals with transparency and efficiency.

Gianluca mentioned that Chargeurs PCC only works with suppliers who meet strict sustainability standards, using natural and recyclable materials. For example, through Nativa™, part of Chargeurs Luxury Materials, it produces 100 per cent traceable Merino wool.

Through its NATIVARegen™ initiative, Chargeurs promotes regenerative agriculture that promotes balanced ecosystems by protecting soil health, safeguarding animals and supporting farming communities.

Chargeurs PCC sources 90 per cent of its purchases through SMETA-audited suppliers and also enforces a strict Restricted Substances List banning hazardous chemicals.

AMANN Group, a leading producer of high-quality sewing and embroidery threads, has made significant eco-progress with its new state-of-the-art plant in Ranipet, Tamil Nadu, as highlighted by Sanjeev Kumar Grewal, Regional Business Director.

In most dyeing units, chemicals like hydrochloric acid or sulfuric acid are automatically dispersed, but colour matching and dye recipe preparation often still require manual powder weighing in small amounts such as 2 or 3 grams. At the Ranipet plant, the company has advanced this process by introducing an automated powder dispensing system with suction and dosing accuracy down to 1/1000th of a gram, ensuring precise colour matching and high reproducibility even if the same shade is required for 25 years.

This reduces shade variation, especially in difficult colours like black or grey, eliminates re-dyeing or over-boiling that can weaken thread and cuts waste by lowering energy and chemical use.

Gurcharan Kalra, Country Sales Head, AMANN Group, further explained that the plant operates with Zero Liquid Discharge, recovering and reusing 91 per cent of water, with the remaining loss being only through evaporation. Waste sludge is converted into powder using steam from the dyeing process and can be used by other industries. Around 33 per cent to 35 percent of electricity is generated on-site through solar panels, while the rest is sourced from solar and wind joint ventures. A biomass boiler runs on eco-friendly briquettes made from wood, husk and cow dung.

| 91%

AMANN Group’s Ranipet plant operates with Zero Liquid Discharge, recovering and reusing 91% of water, with the remaining loss being only through evaporation. Waste sludge is converted into powder using steam from the dyeing process and can be used by other industries. |

The unit has an annual production capacity of 800 to 2,000 tonnes.

In a similar vein, Neelam Threads has set up an Effluent Treatment Plant to recycle wastewater, shifted from coal to gas-based boilers to reduce emissions and uses only Oeko-Tex-certified yarns and eco-friendly dyes. Operations are streamlined to minimise resource use, with its Delhi office powered entirely by solar energy and lit with LED systems.

For sourcing viscose filament yarn, it works with Aditya Birla, a supplier holding both FSC and Oeko-Tex certifications. For recycled embroidery threads, it sources raw yarn from GRS-certified suppliers and dyes them using Oeko-Tex-certified dyes within its facilities.

Ayka Zipper too uses an ETP to treat and reuse all its water. It also uses cleaner Piped Natural Gas instead of diesel, recycles plastic used in production and avoids using raw materials linked to unethical mining.

Likewise, Sharman Udyog’s closed-loop water recycling saves 15 million litres annually, while energy-efficient laser cutting has cut material waste by 20 per cent and energy use by 15 per cent. “An ISO 14001-certified system helps reduce solvent use in heat transfers by 40 per cent, earning a 25 per cent rise in orders from a major EU brand,” said Piyush Jain.

| “Demand for sustainable trims has grown by 40 per cent in the last three years. One major Indian apparel brand recently shifted 100 per cent of its tag orders to our plastic-free option, contributing to a 10 per cent revenue boost in our sustainable product line.” Piyush Jain, Director, Sharman Udyog |

| “We’ve worked with exporters for over 30 years and many now require sustainability certifications—especially those catering to European and US markets. Most demand certifications like FSC, GRS, Oeko-Tex and GOTS to meet buyer compliance and boost product value.”Ankit Jain, MD, Neelam Threads |

| “We’ve seen a 30 per cent year-on-year rise in orders for our Ayka Zippers, which are made using sustainable materials and eco-conscious processes.”Aabhas Arora, MD, Ayka Zipper |

Describing their sustainable metal processing, Nishi Vora, Director, Fashion Accessories India Pvt. Ltd., a manufacturer of all kinds of labels and patches and part of the RCBC group, said that brass waste is returned and remade into sheets, while zinc alloy is recycled on-site without losing quality. Their metal collection saves 50 per cent – 60 per cent energy and water by eliminating electroplating. Also, stone and powder treatments give buttons a vintage look while reducing water use by 16 per cent.

| Brand Nomination Criteria

Quality and Consistency: Brands prioritise high-quality, consistent products that meet specific technical and aesthetic standards. Sustainability and Compliance: Brands increasingly seek suppliers with strong reputation, ethical practices and sustainability certifications (like Oeko-Tex, FSC, GRS) that align with their green initiatives and compliance requirements. Innovation: Brands favour suppliers offering innovative products or solutions to help them stand out in a crowded market. Reliability and Timeliness: On-time delivery and the ability to meet fluctuating demands are critical. Brands expect suppliers to consistently meet deadlines and adapt to changing requirements. Pricing and Flexibility: Competitive pricing is important, but flexibility in meeting varying order sizes and offering customised products can also influence the nomination process. Capacity and Scalability: Brands look for suppliers who have the capacity to fulfil large orders and can scale with them as their needs evolve. |

New Innovations Driving Product Breakthroughs

Manufacturers are constantly pushing boundaries to deliver smarter, innovative and more efficient products. For example, Freudenberg has introduced a 100 per cent biodegradable cotton shirt interlining and a 100 per cent recycled stretch interlining made from Thermoplastic Polyurethane. Its super elastic Stretch Active Range offers good stretch and shape for all kinds of activewear. Made from fully recycled, GRS-certified materials, these interlinings are suitable for waistbands on leggings, stretch jeans and casualwear.

Charguers too has developed H2, the lightest 3-layer technical outer fabric in the market, weighing just 45 grams. Created in France using exclusive Warp-Knit / Weft-Insert technology, H2 offers superior stability, breathability and durability. It is designed for high-end athleisure and outdoor luxury markets.

“We are planning to invest in India, which we see as an increasingly strategic market.. Our goal is to establish a strong local presence, potentially through a partnership with a major local player,” said Gianluca Tanzi.

Madeira has launched light-reflecting threads that glow in the dark, perfect for adding special effects to machine embroidery on clothes and accessories. These threads work well for kids’ clothing, Halloween and carnival items.

It also introduced E-ZEE WATER SEAL, a waterproof film raincoat and other waterproof items. It stops the water from penetrating through the holes created by the needles while embroidering.

Neelam Threads is also innovating with matte finish embroidery threads designed for export market, ideal for fashion trends where a glossy look is not desired. It offers thicker, stronger threads for dori tassels and handicrafts, which work well on heavy fabrics like denim, jackets and upholstery, giving extra durability for both fashion and industrial uses.

Meanwhile, AMANN Group is pushing the boundaries in technical threads by collaborating with DRDO and IITs, highlighted Arun Mishra, MD. They are developing advanced threads such as sensory threads that respond to touch or environmental changes; conductive threads used in military uniforms and gear, especially in extreme conditions like the Himalayas where temperatures drop to -45°C; and forensic threads that are tamper-proof and used in high-security applications like passports to ensure document authenticity.

At the same time, Ayka Zipper is currently experimenting with biodegradable polymer compounds to create zippers that naturally break down.

Through its Green Heart initiative, Sharman Udyog is creating eco-friendly collections using certified materials like 100 per cent bamboo fibre labels and ReThread Tapes made from 80 per cent recycled PET. In 2023, the lineup included plant-based ink tags that reduced chemical use by 50 per cent. Green Heart products now contribute to 25 per cent of the company’s sustainable revenue, with brands like Aditya Birla Group and a major European retailer using them in their premium lines.

The company aims to convert all warp yarns on its woven label machines to recycled polyester by the end of 2028.

It also introduced MetallicWeave Tapes, made with reflective threads for sportswear safety and GlowCraft Badges using photoluminescent pigments for night time visibility.

The company is now eying entry into Canada and North American region.

(With exclusive inputs from Anjori Grover Vasesi)