Before setting up a new factory it is imperative for the apparel manufacturer to know whether the time and market is ready for it or not. But there is no hard and fast rule. The manufacturer should plan much ahead and base his decision on his current manufacturing capabilities, output and performance. The company should be running its existing apparel unit at 65% efficiency before considering setting up another for making the same or similar products. “There are cases where a factory is running at a much lower efficiency but is putting up another facility because it has excess orders coming in. Moreover, an apparel manufacturer cannot say no to perennial orders and business,” asserts CJ who believes that there is no point being in business if you are working at more than 65% efficiency and still not making money.

Most apparel manufacturers are not worried about the type of products they will make when setting up more than one factory as they can make any kind of product within the same facilities. Product-specific manufacturing plants are set up only when there is a huge demand for the specific product. But from a practical point of view, multi-product factories with product-specific sewing lines are actually feasible in case of shirts, trousers and suits, but jeans cannot be made in a factory that manufactures shirts. “The nature of manufacturing processes and the technology required to sew will determine company’s capability in making any two products in the same facility,” explains CJ.

CJ is also of the opinion that factories should (ideally) be of 1,000 sewing machines or even less. “The reason for this is not judicial, rather it is because of the absence of strong human resource management systems and the inability of most companies to handle their workforce beyond a certain number,” he says. According to CJ, a better practice for scaling up the business is to have several factories of 500 sewing machines each of one particular size within short distance of each other, such that this cluster of small factories can be managed efficiently with a central management system.

For managing factories in multiple-locations, a company would have to put in place a well-defined reporting system, a transparent ERP and robust SOPs. When systems are in place, dependence on workers in that place or region is reduced by 50%. If there are SOPs for processes such as pre-production, line setting, etc., then it is as simple as to copy and paste. The major reason why multi-location factories fail is because when the top management is not based in the premises, the workers tend to take liberties and do not follow the SOPs. All the multi-national apparel companies are operating on the same principle globally.

For apparel manufacturers keen on expanding their business operations, setting up new manufacturing facilities would be a definite way to grow their business, but first they would have to consider ‘when, where and how’. Chandrajith Wickramasinghe (CJ), CEO, Corrigo Consultancy, with almost 20 years of experience in the apparel and textile industry of India and Sri Lanka, shares insights on how to set up an efficient multi-storey apparel factory.

Inside a facility

Deciding whether to go for a single-storey or a multi-storey facility depends on the availability and cost of land. In a multi-storey facility, heavy machinery used in knitting, embroidery and washing can be installed, but first the owner will have to enhance the load bearing capacity of the building beyond the industry standard of 300 kg per square feet on each floor. “Although the manufacturing efficiency is almost 10% higher in a single-storey factory as compared to a multi-storey (due to smoother material flow, easier management and better space utilization), these advantages are greatly reduced due to the high construction cost,” says CJ.

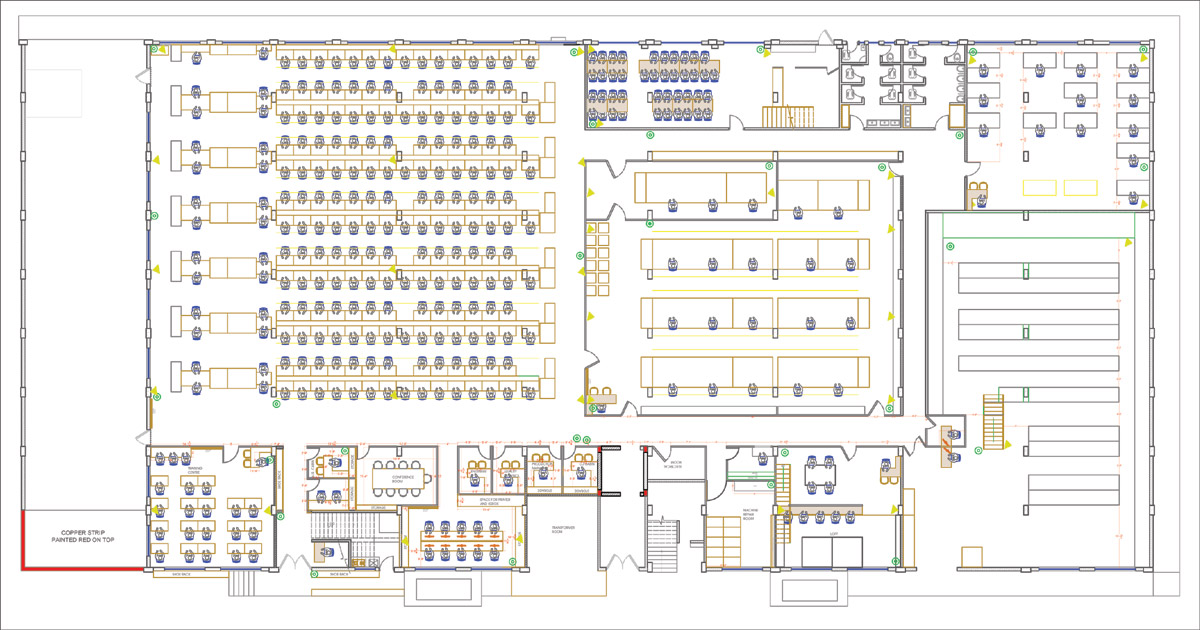

While allocating different processes to the floors in a multi-storey setup, people follow the thumb rule of keeping heavy items on the ground or lower floors. The fabric storage, cutting and finished goods warehouse are either in the basement or on the ground floor, the finishing division is on the top floor, and the sewing division lies in-between. “We can even bring the fabric to the top floor as it comes in bulk and can be sent up easily through a fork lift. Similarly, the cut parts and garments can be brought down with gravity feed,” explains CJ. Generally, the fabric and finished goods warehouse are the only departments that are restricted to the ground floor or to the basement, but the rest (cutting, sewing, finishing, final checking and packaging) can all be placed on the same floor, while the finished/packed goods can be sent straight to the warehouse. “200 sewing machines on a floor have enough consumption of cut parts to have its own cutting setup, instead of being fed by a centralized cutting,” says CJ. The advantage of having numerous departments on a single floor as part of the sewing lines is that it reduces dependence on the central lift, which is only used for sending fabric to every floor and for sending packed cartons to the finished goods warehouse.

Paragon Apparels, one of CJ’s projects, has been designed on similar lines. There are three floors with cutting, 220 sewing machines and finishing on each floor, while the fabric and finished goods warehouse is on the ground floor. A similar setup is also followed at Maral Overseas and Theme Exports. “The only problem in such a setup is when the product has to go out of the sewing line for some other process before its finishing, as with denim jeans, which have to be washed before finishing,” admits CJ. Even oversized machines, such as pocket welting automates required during part preparation, are integrated with the cutting department.

According to CJ, there are many other small and big issues that will have to be addressed when setting up a manufacturing facility, for which he suggests that a checklist be created before initiating the project. For instance, the lint generated in the knitting unit, or the fluff generated when cutting fleece-type fabrics, are issues that must be considered while allocating spaces for different processes. Enclosing the fabric cutting area, and equipping the sewing machines with suction systems to control the lint/fluff and prevent them from sticking to garments that are ready for packing and despatch, are preventive measures that must be factored in during the layout planning stage. “In the case of a composite unit, if a lot of fluff is created in the cutting and sewing department, then these departments should be enclosed and built at a distance from the knitting department as the fluff can get into the knitting machines, which would end up producing defective fabrics,” concludes CJ.