Recent surveys on cost of manufacturing in Asia have indicated that a 2% increase in productivity could be worth $ 80,000 to $ 1,60,000 per 1,000 sewing machines per year depending on the factory location. Many business houses have invested heavily in the latest cutting, sewing and pressing machines to enhance productivity and improve efficiency. But ‘faster’ alone does not guarantee the highest levels of productivity. Often the easiest and most effective way to improve factory productivity is not to focus on sewing faster but to make sure that your operators spend more time sewing without wasting much time.

Several companies have not yet optimized their productivity because they have only looked at half the equation. Continuing with the planning series, Team StitchWorld explores how production planning softwares can make the planning processes of production an effortless job.

Productivity is a factor of output upon input. Output = Speed of the Operator (in Pcs./hr.) X Time spent on Work (in hours). How much sewing time do your sewing operators lose every day? It is commonly accepted that operators spend at least 20% of their time without any work. The reasons why they are not productive are typical:

- Delays due to missing fabric, accessories or style approvals;

- Holdups caused by cut, print and embroidery bottlenecks, besides WIP shortages;

- Stoppages caused by shortages of certain types of machines; and

- Further hindrances caused by style change due to above problems.

[bleft]A common problem which most companies face is the proper prioritization and communication of what they need from their suppliers and when. FastReact provides clear targets for each order/material item, based on ‘how much and when required’ in time for production.”– Glen Walker, Finance Director, Dewhirst of UK[/bleft]

Typically these problems are ‘avoidable’ as they are caused by poor planning, inadequate communication and lack of coordination. It is not surprising that in today’s apparel factory, with so many styles, more complicated designs, changing buyers’ requirements and with shorter lead times, it is not an easy task. Besides, one has to keep up-to-date with the latest status of hundreds of styles and trends in vogue, and also making sure that you and your team, along with the suppliers are clear about the priorities.

Today, when most manufacturing business houses even in low-cost countries, are increasingly faced with the problems of rising costs and ready availability of skilled labour, the labour cost advantage along with long-term survival chances are rapidly getting shrunk. Maintaining profitability is now increasingly dependant on improvements in productivity. Working faster cannot alone improve the productivity. We need to utilize all resources most of the time and reduce any idle time. To do that, plan in a better way, communicate clearly and quickly, see and solve problems as soon as they occur and these actions will reduce non productive time and increase productivity. Only proper planning can lead to effective utilization of your resources including material, labour and time.

But how can we plan and communicate better? Sure, companies and people are already putting maximum efforts but the companies which rely on simple manual tools such as spreadsheets, reports and emails find it increasingly difficult to cope with the complexities of planning and inevitably result in low efficiency and high overheads. On top of it, the management time is wasted in trying to identify priorities due to lack of visibility. Problems are often not visible until it is too late to avoid excess costs or late deliveries. Staff fails to test out different ‘what if’ scenarios when planning quickly. It results in poor decision making as all alternatives are not being considered.

Central Planning to Save Time

For any factory much of the time is typically spent in numerous meetings, emails and phone calls to communicate the frequent changes in the plan. In short, with prevailing manual systems, too much time and effort is spent on simply identifying the problems in the first place, leaving far too little time to solve them. The management could utilize this lost time managing and planning all these systems in a better and proper way and provide guidance to the improvement of business.

To plan effectively, there are many variables to consider including capacity, lead times, material availability and current production progress against the plan… If even one of these variables change on a single order, it may adversely affect other styles and orders. A specialized software solution can only allow the immediate affect to be seen, not just on the order involved, but also on all other orders.

Better Communication and Prioritization

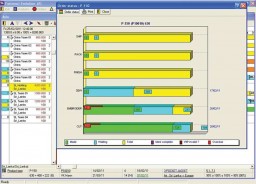

FastReact generates work schedules for all departments and subcontractors from the master production plan. Any WIP problems, such as insufficient cut work coming through for sewing, are immediately highlighted with a colour coded bars.” – P. Sundararajan, Managing Director, S. P. Apparels, India

Another common problem which most companies face is the proper prioritization and communication of what they need from their suppliers and when. “FastReact, the specialized software solution provides clear targets for each order/material item, based on ‘how much and when required’ in time for production. These targets are calculated on Just In Time (JIT)/Lean principles, so clear priorities are set directly from the latest production plan. It enables closer coordination of functions within the business and this even facilitates better materials planning process. It has also directly resulted in the stockholding on materials being reduced by 40-50% (25-30 days stockholding down to an average of 15 days), at the same time improving the raw material availability to the production floor,” says Glen Walker, Finance Director, Dewhirst of UK.

“Moreover, it can be used in co-ordination with other softwares frequently used to manage your production,” says Sherman Lau, President, Elegant Industrial Company, Hong Kong. Totally satisfied with this feature, he further adds, “By selecting FastReact to work with our SAP business system and GPro shop-floor system, we have selected the Best of Breed applications to work together to provide the total solution for all our business needs.

Bottlenecks Due to Frequent Changes in Plans

Many factories fail to see far enough in advance that they may have an overload or bottlenecks on some operations or processes. This may be due to the style mix at a particular time resulting in machine shortages on certain machines in sewing, or capacity problems either before or after sewing on operations such as embroidery, washing or sandblasting, etc. With an ever-changing plan, it can be difficult to keep track of the style mix and loading on key machines or processes. With manual and spreadsheet based systems, this can be an almost impossible task.

“Earlier, it had been difficult and a time-consuming job for us to make a production plan for even 50 production lines. FastReact on the other hand has helped us make planning for over 100 production lines in a much simple way. There are several other additional benefits that we are exploring,” avers Purid Thanalongkorn, Managing Director, Jintana Apparel Co. Ltd., Thailand, a fairly satisfied user of FastReact which allows him to define which operations and machines he wishes to monitor. As soon as the main sewing plan is created, the operation bar-charts provide an easy to read monitor of the loading on key machines or process areas. Potential overloads and problems are highlighted well in advance (by operation and by day/week/month), plenty of time to take corrective action. Full drill down and ‘modelling’ of capacity and working hours, etc. allow for rapid ‘what if’ problem solving.

Smooth Production Flow

For many factories, day-to-day production problems result in insufficient work for certain production lines. Many factories lose output as they have not cut/ embroidered/printed the correct orders or the sufficient quantities to feed the production lines. This regular phenomenon occurs as a result of numerous and necessary changes to the production plans and not being able to quickly communicate the latest requirements/priorities to each department.

Getting vocal about his experience with FastReact, Krishna Kumar, Chief Executive Officer, Integra Apparels and Textiles, India says, “We find that the planning board is the most used feature at our facility since it enables us to quickly and accurately plan and re-plan processes, besides providing a fantastic bird’s eye view of all orders simultaneously. We expected payback in 18 months’ time and we are on course to better that.”

“FastReact generates work schedules for all departments and subcontractors from the master production plan (e.g. sew). Any WIP problems, such as insufficient cut work coming through for sewing, are immediately highlighted with a colour coded bars. It has improved our On-Time Delivery Performance (OTDP) and has contributed to our sales growth. Good planning is fundamental to success in today’s fast moving apparel industry. In our experience, the return on investment was around six months from full implementation,” claims P. Sundararajan, Managing Director, S. P. Apparels, India.

Softwares allow you to plan and communicate better: If you can plan better to start with, there will be fewer surprises, and both management and suppliers will receive clearer priorities. Potential problems will be seen in advance and there is more time to fix them. In the inevitable cases where things do go wrong, specialized software solutions allows for quick ‘what-if’ planning to find and evaluate different solutions.