Ask any leader, whether from a brand, retail or investment side, what category they think will boom in the coming years and nine out of ten will tell you ‘activewear’.

Once seen as niche, it has exploded into a lifestyle essential, blurring the lines between gym, office and casualwear. The activewear market is booming worldwide and India is right in the thick of it. Our athleisure market, already valued at US $ 13.5 billion in 2024, is set to reach US $ 21.25 billion by 2033.

Yet, despite this growth, India still doesn’t have the ecosystem to supply high-performance activewear fabrics at scale. Even when the fabrics are made here, the raw material is usually imported from Taiwan, South Korea or China.

The gap becomes glaringly evident when you walk into any leading activewear store and see labels stating ‘Made in Vietnam’ or ‘Made in Bangladesh’.

At the core of this gap are speciality fibres and advanced yarns. Take spandex, the backbone of stretch and performancewear. To make it, ingredients such as PTMEG (Polytetramethylene Ether Glycol) and MDI (Methylene Diphenyl Diisocyanate) are required. The former is made by polymerising tetrahydrofuran, is prized for its elasticity and resilience, while the latter reacts with polyols to form the polyurethane that gives spandex its characteristic stretch. Both are produced on a large scale in China, making India dependent on imports.

Similarly, advanced fibres like Elastomultiester (EME), sold under names like LYCRA® T400, are largely manufactured in China. EME achieves stretch and recovery without spandex by combining two different polyesters that shrink differently, another innovation that India has yet to scale.

Building a self-reliant activewear ecosystem requires investment across fibre production, fabric processing and machinery.

Also Read: Sportswear Fabric and India’s Challenge

Bridging the Supply Chain Gap

Despite the challenges, leading players are steadily working to build a strong ecosystem for activewear.

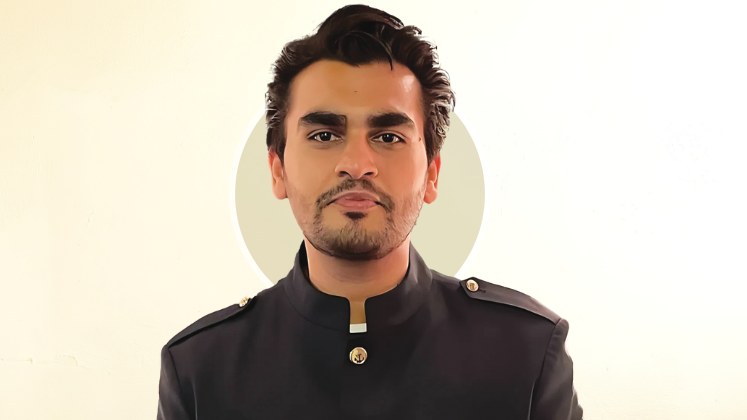

“Over the past five years, our dependence on imported performance fabrics has significantly reduced, thanks to the efforts and investments of our supplier partners. India now has a more integrated and capable textile value chain from yarn production to advanced fabric processing. Our goal is to make India a global hub for performance activewear fabrics in the near future,” said Watsh Wardhan, Textile and Apparel Production Head India, Decathlon.

He added, “We’re actively working with Indian suppliers, mills and tech partners to co-develop fabric innovations. This includes advanced finishes like antimicrobial and anti-odour treatments, durable wicking and water-repellent properties. We’re also developing stretch yarns as reliable local alternatives to elastane or spandex and using sustainable materials such as recycled yarns, bio-based fibres and low-impact dyeing techniques.”

Watsh stressed that to support these innovations, it’s essential to build local testing laboratories that follow global standards, enabling scientific validation of performance and faster product development.

“We source roughly 60% of our performance polyester yarns through imports, while the remaining 40% of standard polyester comes from local suppliers. Similarly, about 60% of our dyes and chemicals are of Indian origin, with the rest imported,” said Puspen Maity, CEO of TechnoSport.

The activewear brand plans to expand its presence in India, aiming to open 50 new outlets by the end of the year, adding to its current network of 15 EBOs.

Pushpen claimed all their fabrics come with high moisture management, permanent UV protection of UPF 50+, good mechanical stretch recovery, over 98% anti-microbial efficacy lasting up to 50 washes, anti-static properties up to 50 washes and are at least 30% lighter than fabrics of similar thickness.

Despite the expansion plans, he noted that local suppliers are still a few steps behind global benchmarks when it comes to polyester filament yarns. Products such as fine micro full dull polyester yarns and mechanical stretch polyester filament yarns, which are already widely available and commoditised in mature markets, are still treated as speciality here, with quality standards yet to fully evolve. On the elastane side, however, the situation is improving, with local availability having strengthened in the past 2-3 years with better production quality, reducing our reliance on imports.

| “We source roughly 60% of our performance polyester yarns through imports, while the remaining 40% of standard polyester comes from local suppliers. Similarly, about 60% of our dyes and chemicals are of Indian origin. For making activewear fabrics, fine-gauge knitting, warp knitting machines, continuous deoiling and long tube jet dyeing machines are key.” Puspen Maity, CEO of TechnoSport |

“In India, brands like Creora and Inviya manufacture a respectable amount of spandex with the goal of gaining at least 70% of the market. Regarding the other specialty yarns, Madhusudan, Reliance (R|Elan) and Sanathan are performing admirably and strengthening India’s position as a leader in high-performance yarns. Indeed, there are still a lot of new developments that are not manufactured domestically in India; ideally, additional partnerships with eastern producers like Far Eastern, Everest, Eclat, etc., would be necessary,” said Kishan Daga, Founder Anchor, Concepts N Strategies. The company specialises in the activewear and athleisure industry, providing innovative workshops and consulting to help clients achieve better results.

“One of the main raw materials for activewear is nylon fibre or nylon yarn, but it is almost entirely unavailable in India. About 99.99% of it is imported. A few companies like Century Enka of the Aditya Birla Group, produce Nylon Filament Yarn (NFY),” said Sanchit Sarawgi, Owner, Sarawgi Group, a Surat-based manufacturer of circular knitted fabrics.

The company makes a wide range of fabrics such as polyester spandex single jersey and interlock, polyester interlock and single jersey fabrics, spun/viscose for leggings, hosiery fabrics in solids and prints for nightwear, printed knitted fabrics, polyester printed fabrics, yarn-dyed knitted fabrics, scuba fabrics in solids and prints (sandwich and plain) and knitted fabrics for both menswear and womenswear.

| “The core machines include circular knitting machines, which produce stretchable, seamless and lightweight fabrics ideal for leggings, T-shirts and performance tops; warp knitting machines like Raschel and Tricot, which create stable, high-recovery fabrics essential for compressionwear; flat knitting and Jacquard machines, which enable knit patterns that reduce seams while improving comfort and are increasingly being scaled up in India.” Aditya Agarwal, Co-founder, Campus Sutra |

Sanchit explained that activewear fabrics require four main types of nylon yarns: 40DDS, 70DDS, 110DDS and 150DDS. These yarns form the backbone of activewear production, but India does not manufacture all of them. While Reliance supplies polyester locally, there is currently no domestic source for these nylon yarns. As a result, they are imported from the South Korean company Hyosung to produce pure nylon fabrics for activewear.

| “One of the main raw materials for activewear is nylon fibre or nylon yarn, but it is almost entirely unavailable in India. About 99.99% of it is imported. A few companies, like Century Enka of the Aditya Birla Group, produce Nylon Filament Yarn (NFY).” Sanchit Sarawgi, Owner, Sarawgi Group |

In spite of the limitations, local players are also focused on self-reliance.

“Over 90% of our raw materials, including spandex, are sourced locally. Only specialty yarns like bi-component yarns such as Elastomultiester, which are not available in India, and Siro yarns, where production is limited, are imported,” said Jay Jayesh Shah, Director, Meera Cotton and Synthetic Mills, a vertically integrated manufacturer producing 120 tonnes of fabric daily.

Recently, the company has developed high-performance fabrics that were earlier imported, including polyester with up to 27% spandex, nylon with up to 38% spandex, scuba fabrics with high spandex content in polyester and poly-viscose blends and finer-gauge Elastomultiester mechanical stretch compact fabrics.

All fabrics have basic wicking and antistatic properties and most have inherent UPF 50++. For some buyers, perpetual wicking lasting the garment’s lifecycle is provided.

The company’s machines are configured for microfilament and elastane yarns and it operates one of the largest number of open-width machines in India. Daily yarn consumption is nearly 100 tonnes for yarns with 72 or more filaments and up to 144 filaments are used for finer deniers like 75D and 50D.

Machinery: The Heartbeat and Bottleneck of Activewear

Machines are the backbone of activewear production and having the right ones makes all the difference. “For making activewear fabrics, fine-gauge knitting, warp knitting machines, continuous deoiling and long tube jet dyeing machines are key. Along with that, reasonable process control is required to maintain precision through Industry 4.0 data monitoring and data analytics systems. We have all of these in-house,” claimed Pushpen Maity.

| “Over the past five years, our dependence on imported performance fabrics has significantly reduced, thanks to the efforts and investments of our supplier partners. India now has a more integrated and capable textile value chain from yarn production to advanced fabric processing.” Watsh Wardhan, Textile and Apparel Production Head India, Decathlon |

However, in fine-gauge and warp knitting, capacity is still limited and processing technology is largely outdated. Operational expertise is also a gap. “The real opportunity lies in aligning raw materials with machinery. Only when raw material standards move up the value chain will high-end processing fully mature,” he added.

Similarly, Aditya Agarwal, Co-founder, Campus Sutra, a youth-focused brand, emphasised that activewear production depends heavily on specialised machinery from Germany, Italy and Japan, including Karl Mayer, Mayer & Cie, Santoni, Lonati, Shima Seiki and Fukuhara.

“The core machines include circular knitting machines, which produce stretchable, seamless and lightweight fabrics ideal for leggings, T-shirts and performance tops; warp knitting machines like Raschel and Tricot, which create stable, high-recovery fabrics essential for compression wear; flat knitting and Jacquard machines, which enable knit patterns that reduce seams while improving comfort and are increasingly being scaled up in India. Also bonding, ultrasonic and seamless stitching machines replace traditional seams with heat-bonded or ultrasonic finishes and are now being used in performance wear beyond undergarments,” said Aditya.

| “Over 90% of our raw materials, including spandex, are sourced locally. Only specialty yarns like bi-component yarns such as Elastomultiester, which are not available in India, and Siro yarns, where production is limited, are imported.” Jay Jayesh Shah, Director, Meera Cotton and Synthetic Mills |

Sanchit too concurred that machinery remains India’s Achilles heel. Nylon yarns require fibre machinery that converts POY (partially oriented yarn) chips into nylon yarn through polymerisation and polyester needs a similar process. Machines from the German company Oerlikon Barmag are essential to produce high-quality yarn because they control tension and variation. While India has POY machines, the advanced machinery to process POY into high-quality yarn like DTY is very limited. Only a few polyester yarn manufacturers, such as Reliance and Wellknown Polyesters Ltd., have it, and in the nylon segment, no company currently does.

Dyeing is another critical area. Modern chemicals like UV protection, moisture-wicking and antimicrobial agents are available, but advanced dyeing vessels from Fong’s and Thies GmbH & Co. KG, which offer fully automated liquor flow and chemical dosing at controlled temperatures, are rare in India. Local machines cost Rs. 15-25 lakh, while Fong’s or Thies machines cost Rs. 1-1.5 crore.

| “In India, brands like Creora and Inviya manufacture a respectable amount of spandex with the goal of gaining at least 70% of the market. Regarding the other specialty yarns, Madhusudan, Reliance (R|Elan) and Sanathan are performing admirably and strengthening India’s position as a leader in high-performance yarns.” Kishan Daga, Founder Anchor, Concepts N Strategies |

In local dyeing, chemicals such as Black dye, softeners and lubricants are added manually, while in Vietnam or China, automatic dosing ensures consistent colour and quality. In India, the lack of automation, technical know-how and discipline leads to inconsistent dyeing results. With proper systems and training, consistency can be achieved.

The recent GST revamp will give a much-needed shot in the arm to the activewear industry. “Man-made fibre raw materials were always expensive in India due to QCO and the inverted GST structure and led to a surge in imports of MMF fabrics and garments. By reducing GST on man-made fibre raw materials and yarn from 12-18% to 5%, the government has taken a pivotal step to make the sector more competitive,” said Watsh Wardhan. Experts also mentioned that activewear is moving towards sustainable, high-performance yarns, including recycled polyester made from PET.

India’s activewear progress is underway, but the real winners will be the brands, manufacturers and investors who tackle the fibre, yarn and machinery gaps today, turning import dependence into homegrown innovation.