Apparel for men, women and kids. Sneakers hitting the streets. Handbags turning heads. Workwear built for tough shifts. Bathrobes, towels, bedsheets and cushions that comfort. Swimming costumes riding the waves. Horse saddles built for control and confidence. Uniforms that serve the Indian Armed Forces. Footballs powering the world’s most loved sport. Car seats built for everyday journeys. Cricket balls uprooting stumps. Cricket pads absorbing every impact. And the India team jersey carrying the pride of millions of fans.

What’s the one element that runs through them all? Threads…from Coats, a world-leading Tier 2 Supplier of critical components to the apparel and footwear industries.

To understand how the company is meeting the evolving demands of its customers, Apparel Resources was invited to Madurai to meet with the Coats leadership team, including David Paja, Group CEO; Adrian Elliott, Apparel CEO and Group Chief Commercial Officer; and Pasquale Abruzzese, Footwear CEO and Group Chief Operating Officer.

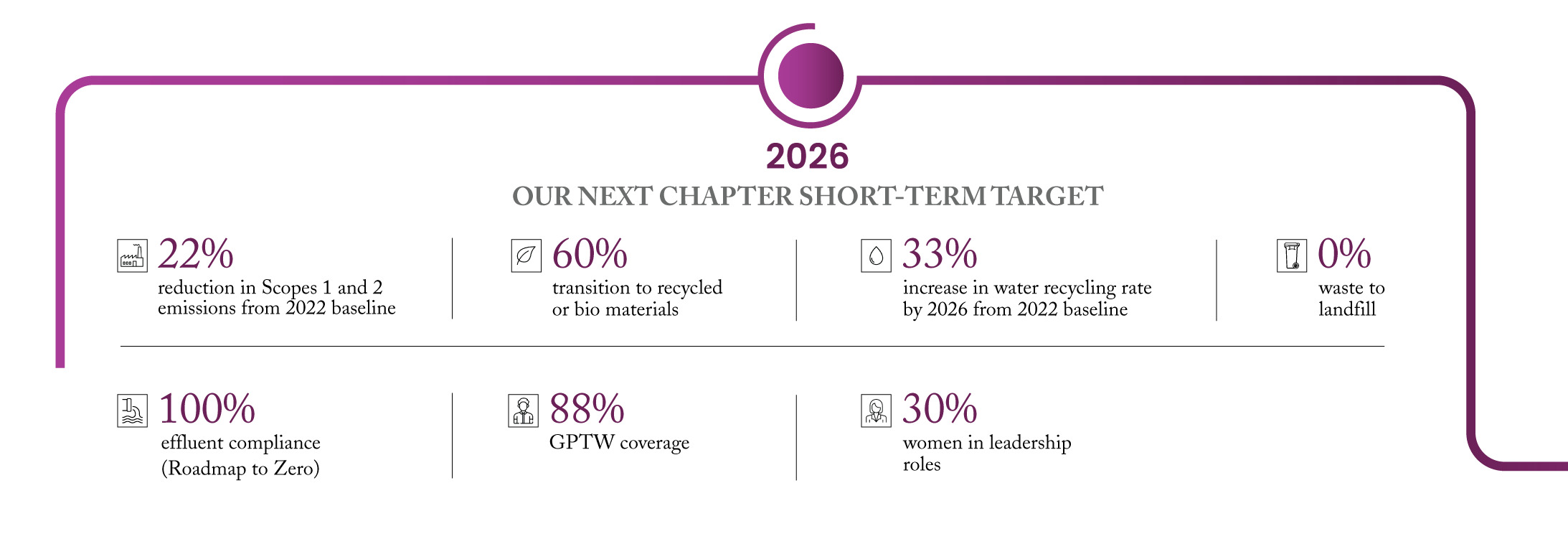

Several clear themes emerged from our conversation. Sustainability remains essential, with over half of Coats’ portfolio already made of preferred non-virgin oil-based materials, and circular solutions on the horizon. Footwear innovation is accelerating, highlighted by the OrthoLite acquisition in 2025, building on earlier moves with Texon and Rhenoflex in 2022. Together, these acquisitions give Coats unmatched capabilities across insoles, structural components, and reinforcement materials.

Technical textiles, especially protective apparel, are shifting from compliance-driven products to high-performance, comfortable solutions. At the same time, uniquely Indian businesses, like kite thread and support for local tailors, showcase the company’s deep understanding of the domestic market.

Digitisation of the supply chain is another key focus, helping brands and manufacturers make faster, smarter decisions. Employee well-being also stood out in our discussion, seen as critical not just for business growth but also for attracting and retaining the right talent in today’s competitive landscape.

Despite the US-imposed tariffs on India, Coats remains optimistic about the future of the Indian apparel and footwear market. Excerpts:

AR: Mr. David, we last spoke to you last year when you had just joined and were settling into your role. Now, looking ahead, what are your key focus areas, and what trends do you see shaping the apparel and footwear industry?

David Paja: After almost a year here, the mission remains simple: create more value for our customers. We work with over 1000 brands and 25,000 manufacturers, and our priority is to stay a partner they trust every single day.

We’re focusing on four areas where we can make the biggest impact: sustainability, footwear, safety solutions, and digital transformation across the global supply chain.

At the same time, the products our customers make are changing. Athleisure and comfort-first clothing are now the norm, which means seams need to stretch, move, and feel soft against the skin. We’ve developed solutions like Seamsoft for softness and stretch, Surfilor for smooth and premium-feel seams, and Eloflex for high elasticity without losing strength.

Overall, we see a huge opportunity ahead. We’re strengthening what we do best so we can support the industry’s next phase of growth.

| “We have developed Textile-to-Textile sewing threads available in T2T Epic and T2T Gramax variants. These “proof of concept” threads are made from textile waste using a chemical recycling process. They deliver the same strength, durability, and colour fastness as standard Coats threads and can be seamlessly switched out on the sewing machine lines without any downtime.” – Adrian Elliott |

AR: Let’s decode your big priorities one by one. Starting with sustainability, what real impact are you delivering for clients that actually moves the needle?

Adrian Elliott: A lot of what we are doing is led directly by our customers. Brands have set ambitious sustainability goals, and they expect partners like us to help them get there. Over half of our products are already made of preferred non-virgin oil-based materials, and we expect that to move close to 60% by 2026. Our revenue for our 100% recycled thread products also went up by 144% to US $405 million in 2024. This gives our customers a very real and immediate improvement in their product footprint.

The next stage is circularity. Customers now want materials that can return to the textile system at the end of life instead of relying only on bottle recycling. We are investing heavily in this area for both apparel threads and footwear components.

For example, we have developed Textile-to-Textile sewing threads available in T2T Epic and T2T Gramax variants. These “proof of concept” threads are made from textile waste using a chemical recycling process. They deliver the same strength, durability, and colour fastness as standard Coats threads and can be seamlessly switched out on the sewing machine lines without any downtime.

The push for sustainability is coming from all sides: end consumers who increasingly care about sustainability, regulations that are evolving fast, and brands that do not want to fall behind or be seen as greenwashing. These solutions may sometimes come with a small premium, but they align with our premium positioning, and they help customers deliver on what they have promised. It’s a win-win situation for both our customers and for us.

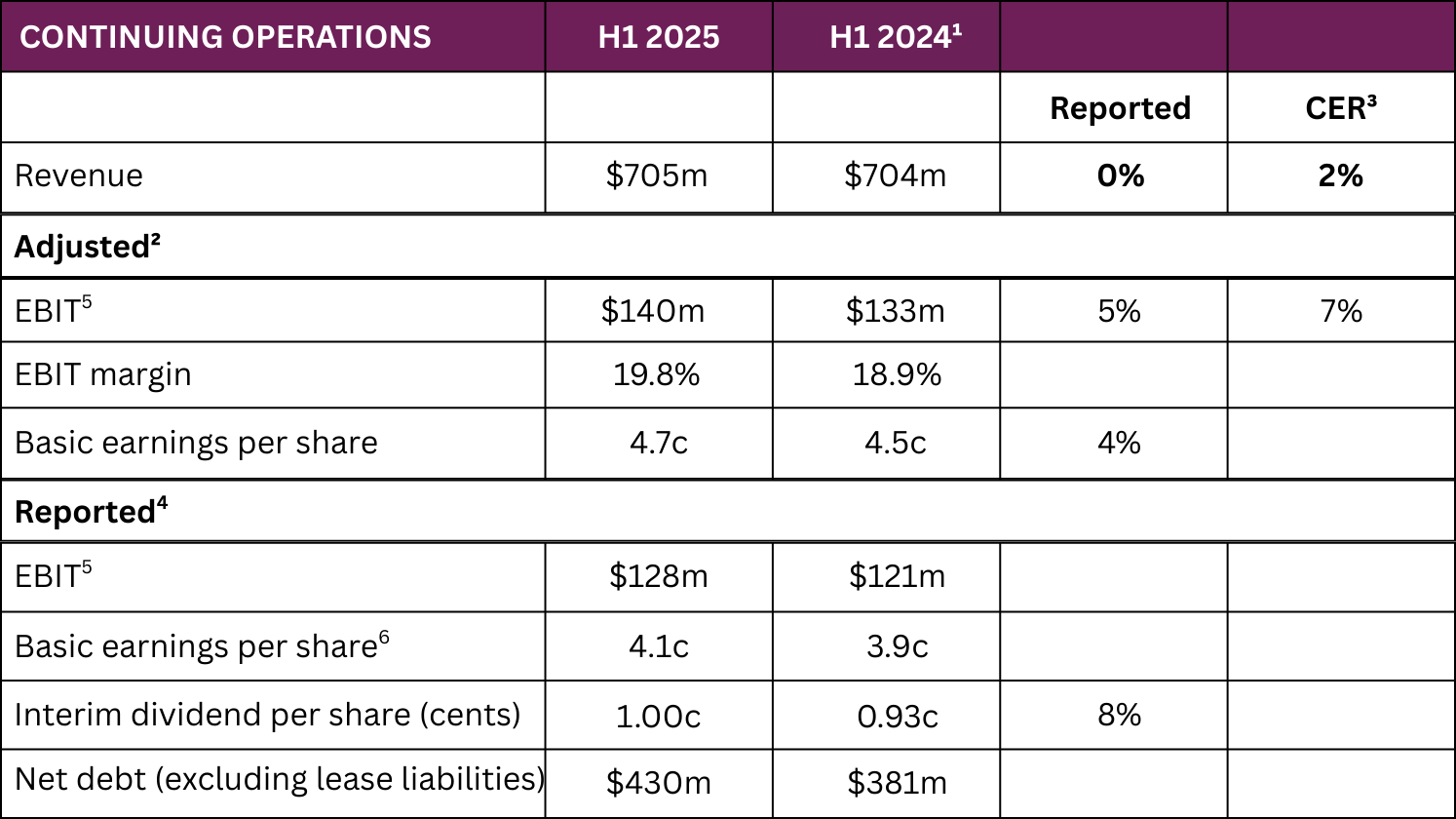

2025 Half Year Results

1. Represented to reflect the results of the Americas Yarns business as a discontinued operation.

2. Adjusted measures are non-statutory measures (Alternative Performance Measures).

3. Constant Exchange Rate (CER) metrics are 2024 results restated at 2025 exchange rates.

4. Reported metrics refer to values contained in the IFRS column of the primary financial statements in either

the current or comparative period.

5. EBIT (Earnings before interest and tax) relates to Operating Profit as shown on the face of the P/L

Reconciliation between the Adjusted EBIT and Reported EBIT.

6. From continuing operations

AR: Digitisation is key to staying ahead and improving efficiency. How is Coats helping the industry embrace it?

David Paja: When I joined Coats, coming from outside the fashion and footwear industry, it was clear to me that the way the industry operates isn’t sustainable. Digitising the supply chain is no longer optional.

This industry is extremely complex, from design to production, and through multiple layers of the supply chain. On top of that, you have faster design cycles, smaller batch sizes, rising costs from tariffs and interest rates, pressure to reduce inventory, sustainability requirements, traceability demands, and the need to cut waste. Without digital solutions, managing all of this is nearly impossible.

What we’re doing is helping clients across every stage of the supply chain.

For instance, our partnership with DMIX, a digital platform by ColorDigital GmbH, helps deliver accurate, standardised digital colour and surface exchange solutions for designers, product developers, and manufacturers. This collaboration is a key part of our digital transformation, supporting centralised platforms for better cross-functional collaboration, from colour development to smoother communication across the value chain.

By using DMIX, we can speed up development, reduce physical samples, accelerate decision-making, and support sustainability objectives.

On the cost and production side, we have GSD Quest, a pre-production cost benchmarking solution. Even staff with little manufacturing experience can use a simple drag-and-drop interface to quickly generate a time and cost analysis for apparel products. For example, you can upload a picture of a jacket, and in 30 seconds, AI calculates stitching time and costs based on 20 years of proprietary data.

Likewise, ShopCoats is evolving into a one-stop platform for placing orders, from simple samples to complex bulk orders across multiple product lines. In 2024, over 80% of customer orders in Apparel were processed through this platform.

The big achievement here is bringing all these tools together in one cohesive platform – which is what we’re doing.

We’ve also focused on making adoption easier. Moving digital solutions to the cloud lowers upfront costs and makes it simple for customers to get started.

AR: Beyond apparel, footwear has emerged as a major strategic priority for Coats, especially with the OrthoLite acquisition this year. What are your main priorities here?

Pasquale Abruzzese: We’ve always been strong in threads and structural components like toe puffs and heel counters. Now, with OrthoLite, we add the insole, the first point of comfort that a consumer feels. This builds on our earlier acquisitions of Texon and Rhenoflex in 2022, which expanded our capabilities in structural and reinforcement components.

In markets like Vietnam and China, our Coats teams are already located close to OrthoLite sites, often less than an hour apart – making collaboration a lot easier. With nearly 4,000 skilled people on the ground, we can respond faster, invest in advanced systems, and drive innovation right where shoes are being developed and manufactured.

We have lots of opportunities to support the varying needs of the footwear industry in different parts of the world. Take India, for example – the country has huge potential in footwear, but unlike apparel, it demands higher skills, heavier investment and stronger technical support to scale manufacturing locally.

This is where Coats can truly help. With OrthoLite already manufacturing in India, and our growing footprint in structural components, we can accelerate local footwear growth, support brands, and build the skills and infrastructure needed for the shift toward sports and athleisure.

We are very focused on innovation in Footwear. Let me share three examples.

Using our Rhenoprint process, we can produce tailor-made reinforcement solutions, such as heel counters and toe boxes, that match the exact requirements of a shoe. It’s very flexible; a designer provides the shape and specification values, and Rhenoflex can produce almost any form, thickness, or hardness.

By combining attributes such as high tensile strength with targeted stretch, or lightweight construction with zonal breathability, our ProWeave technology enables uppers that are both high performing and visually distinctive. Another key innovation is Coats Lattice, a fibre-laying technology to produce carbon plates for running shoes that uses sustainable raw materials such as recycled carbon, basalt fibre, or thermoplastics. This allows precise placement of yarns in any design to control thickness, flex, torsion, and rigidity across the forefoot, midfoot, and rearfoot. The result is footbeds that perform exactly as intended and enhance the wearer’s experience.

AR: As worker safety becomes non-negotiable across industries, how are you supporting your clients to meet these standards?

David Paja: Technical textiles, especially protective apparel, are evolving rapidly as safety requirements rise across India and the world. Fire-resistant clothing used to be stiff and compliance-driven, controlled by a few players with older technology. Today, the focus is on both performance and comfort.

Technical textiles cover a wide spectrum, but we are particularly focused on thermal and protective applications.

Our FlamePro range delivers advanced flame, electric arc, and cut resistance by combining multiple fibre types – each tailored to meet exact performance needs such as strength, heat protection, and anti-static properties – through our proprietary Blend Predictor technology, which helps engineer the right blend of fibres from the start, reducing trial and error, and speeding up development.

Industries like oil and gas, utilities, and defense are expanding, particularly in Asia. These customers already trust us from years of using our threads in protective gear. Today, we provide a broader set of solutions with the same reliability, supporting high single-digit global growth with Asia leading demand.

India’s worker protection standards align with global expectations, but speed and localisation make the difference. The Indian military and other clients have unique requirements, and we have adapted our products to meet them. We now offer full end-to-end capabilities in India, including engineering, customisation, rapid prototyping, and bulk production, enabling fast turnaround from design to deployment.

COATS: THE THREAD BEHIND EVERY PRODUCT

AR: Beyond your core categories, you’re active in some very unique segments, such as kite thread, thread used in cricket balls, and even supporting local tailors across India. What drives this side of the business?

Adrian Elliott: Coats has been in India for almost 140 years, so we’ve developed some very local capabilities. India has its own culture and consumer needs, and we’ve grown with them.

Kite flying is a huge tradition. We’ve been supplying kite thread for decades. It is actually a sizeable, multimillion-dollar business for us, driven purely by Indian culture and demand. The seasonality is strong, and we are right in the middle of production and distribution for the upcoming season.

Cricket balls are different. It is not a large global category, but in India, the passion for cricket is massive. Our thread is used in premium balls, which shows how deeply we are woven into India’s sporting ecosystem.

Another big pillar is the tailoring community. We serve nearly a million tailors across the country through our extensive distribution network. It is a very stable business, and interestingly, ladies’ wear tailoring continues to grow despite the rise of fast fashion. Ameto is one of the most recognised names in sewing thread for tailors.

Beyond industrial and sporting threads, we also cater to personal care segments. Bella, an eyebrow threading product widely used in salons, comes in variants such as aloe-infused, antibacterial, and 100% organic cotton.

Taken together, these products show that India is unique, and Coats is committed to serving its distinct needs.

AR: Coats India is known for its great work culture. What’s your secret to keeping employees motivated, supported, and happy at work?

David Paja: Being people-centric is part of our DNA. With over 250 years of global history, we’ve always valued our employees, and we’ve made wellbeing a central focus. Today’s workforce wants to work for companies that genuinely care about them and operate sustainably, and we take that very seriously.

We’re proud that Coats India has been recognised as one of India’s Best Workplaces™ in Textiles & Textile Products 2025 by Great Place to Work® India. Similarly, we have been recognised among India’s Top 50 Best Workplaces™ for Women 2025 by Great Place To Work® India. These recognitions reflect the initiatives we have put in place to support our people.

Initiatives like Coats For Her are great examples of this culture – from ensuring equal representation in recruitment to fast-tracking women into leadership roles, mentoring, visibility programs, and a world-class crèche in Ambas, we continue to champion inclusion and well-being across the organisation.

We approach well-being holistically through our Energy for Performance program, which covers physical, mental, psychological, and social health. This program runs year-round, with activities ranging from yoga sessions to cricket tournaments. We also run structured training and development programs every three months, either virtually or on-site, to keep skills sharp and support continuous learning.

On the CSR front, we focus on women’s empowerment, health, and education. Our centres in Ambas, Faridabad, and Madurai have trained around 1,000 women, helping them start businesses or gain employment. In health, we furnished the maternity hospital in Ambas, which was originally built by the government. For education, we support three government-aided schools around Ambas. We built a proper kitchen for mid-day meals, increasing the number of children served from 150 to over 500. We also upgraded the toilets to improve hygiene.

All of these initiatives show employees the tangible value of our programs while reinforcing the link between personal well-being, community impact, and business performance. Engaged and well-supported employees consistently deliver better results, and that remains at the core of how we operate.

| “We’re proud that Coats India has been recognised as one of India’s Best Workplaces™ in Textiles & Textile Products 2025 by Great Place to Work® India. Similarly, we have been recognised among India’s Top 50 Best Workplaces™ for Women 2025 by Great Place To Work® India. These recognitions reflect the initiatives we have put in place to support our people.” – David Paja |

AR: The recent US tariffs have shaken up the Indian market. How have they affected Coats, and where do you see the long-term growth potential for India?

Adrian Elliott: The tariffs have certainly had an impact. In the past couple of months, we have seen immediate cost pressures and some short-term shifts of business to other countries. At the same time, we are seeing a rebalancing, with many nonAmerican companies looking to use their freed-up capacities here in India.

We see the disruption caused by the tariffs as a temporary setback, and over time, businesses will get through it. The long-term prospects for India remain strong.

The key drivers for growth in India are increased domestic consumption, footwear expansion, and technical textiles. These are long-term areas for investment, and that is where we are focusing for sustainable growth.

For us, the impact of tariffs has been limited thanks to the diversity of our geographic presence and customer base.