Baseball caps are undoubtedly the most promising product category. It has an existing demand in the western market but now the Indian market for this segment is also growing. Brands, retailers and manufacturers are all witnessing a significant growth in demand for high-quality caps. The rising popularity of streetwear fashion; growth of the e-commerce space (allowing smaller brands to venture into apparel merchandising); fitness fad of Indians are playing their part in this. Increased commercialisation of sporting events, more demand for promotional products are the major factors boosting the baseball caps market.

As per reports, the global baseball cap market size was US $ 17.98 billion in 2021 and it is forecasted to reach US $ 25.64 billion by 2029, growing at a Compound Annual Growth Rate (CAGR) of 5.2 per cent from 2023 to 2030. Indian caps market also rose by 57 per cent in 2022 compared to 2021.

Not only top global sportswear brands and retailers like Nike, Decathlon, adidas, Puma, Columbia Sportswear, BUFF, Asics, but also many other companies, known for fashion apparel and accessories, are focusing on caps such as designers and labels like Hugo Boss, Ralph Lauren, besides cap-specific brands like Dalix and Kbethos.

Similarly in India, domestic brands and players like Urban Monkey, streetwear brands like CAPSUL, Redwolf Apparel, Supervek (Zenative Retail), Haute Sauce, boldfit.in (Bling Brands), fabseasons.com and Shop The Arena are growing in this category.

Many leading caps manufacturers in India are catering to national and international brands like Sambhav Cap Creations, Jasmine Apparels, Kapture Headwear and Nice Caps.

Growth pushing towards expansion in this category

The industry in general is of the opinion that caps is a growing market. Chogori Retail India is one such example. The company is an exclusive distributor of leading outdoor international premium brands in India and has seen a 37 per cent jump from FY 2022 to FY 2023 for caps as a category. It mainly offers premium brands like Columbia and BUFF.

“We are witnessing a growing customer base across all categories of caps on offer. Almost 60 per cent of our revenue for caps this year has been generated from Tier-1 cities and the remaining from Tier-2 cities. However Tier-2 cities have shown a higher growth in demand compared to last year’s sales, than Tier-1 cities,” shared Ankit Kumar, Head-Buying and Merchandising, Chogori Retail India.

The company also witnessed this demand across all channels including wholesale, retail and e-commerce. “We are also trying to enter into the corporate market and increase the width of our range by incorporating newer categories and designs within this segment,” says Ankit.

Decathlon, a leading sports sector company with over 1,700+ points of sale worldwide, has been manufacturing basic caps for a long time and now it has transitioned to technical caps to cater to diverse category users.

The company has users who practise sports extending from beginners to intermediate categories. It designs products based on user requirements, usage and durability. Based on these, the company designs products in a few categories like basic, mid and the technical range.

“Presently, we are seeing the number of sports users increase year-on-year. To cater to this need, we are developing high technical components, investing in automation and advanced machines to deliver all range of cap products within India. Our mid- and long-term goal is also to ensure that we not only ‘Make in India’ for India but also for the world,” said Dinesh Perumal, Headwear Process Leader, Decathlon.

There are renowned Indian brands like Woodland that are witnessing good demand for caps due to various reasons like India’s prolonged summer season, people becoming health-conscious and focusing more on walking, jogging besides growing fashion awareness and increasing disposable income. In exports, the brand is witnessing good demand in Dubai and a few other countries.

Emerging Indian sportswear brand T10 Sports, Gurugram shares a similar experience and its Founder Bijesh Todi stated that they are witnessing rising demand for caps especially as athleisurewear is booming in the recent period.

D2C brands, the disruptors in apparel retail, are also upbeat about the growth in this segment and are expanding in this category. A few of them are associated with top textile companies like The Arena, an apparel merchandise brand focusing on bringing quality authentic sports merchandise to sports fans in India, which is associated with Mumbai-based Suditi Industries. It has introduced an official range of baseball caps, besides selling premier products of US leading brand New Era Caps Company.

Abhinav Gairola, Head, Marketplace, Campus Sutra calls caps a “timeless accessory that maintains enduring popularity.” He is strongly of the opinion that as fashion trends continue to evolve, the demand for caps will continue to grow.

Capsul Collective, a Bengaluru-based multi-brand streetwear D2C retailer, offers brands like HUF, Pleasures and Carhartt WIP to name a few and currently only imports headwear. “We are continuing to stock more styles from more brands. Caps for us is an important accessory that helps complete a fit and we believe in curating statement pieces that become conversation starters,” shared Bhavisha Dave, Co-founder, Capsul Collective.

Opportunities in export

India exported caps (HS Code 65050090) worth US $ 31.72 million in 2021-22 with a de-growth of 4.01 per cent. US, UK and Germany are the major markets in India for caps (see table). Stakeholders in this category are strongly of the opinion that as globally, there is huge overstock of accessories, hence the caps’ trend is not overperforming, but at the same time, they expect good growth in 2024.

India’s cap export to US, UK and Germany

| Country | 2021-22 | 2022-23 | Growth % |

| US | 10.55 | 9.11 | -13.64 |

| UK | 2.97 | 2.92 | -1.62 |

| Germany | 2.32 | 2.73 | 16.11 |

Figures: US $ Source: Govt. of India

Exporting caps to the US, UK, Europe and many other countries, Vivek Khanna, Director, Sambhav Cap Creations, Jalandhar has observed that the US and Europe have seen a particular rise for ‘Made in India’ caps, due to global brands trying to diversify their supply chains.

The company has a current capacity of around 50,000 pieces of baseball caps per month and works with major domestic customers including the topmost sports goods’ brands and e-commerce-based start-ups.

On the other hand, India’s competitor countries are far ahead in this product category as Bangladesh exported caps worth US $ 447.43 million in 2022-23 and it was 22.71 per cent more compared to last fiscal. Majority of the leading cap exporting companies in Bangladesh are from Hong Kong and South Korea and they are able to export this category at the said level mainly due to cheap labour and the availability of skilled workforce.

China is also far ahead of India as it has exports of more than US $ 3 billion in this category and it is constantly increasing for the last two years. US is the biggest importer of caps from China and it has imported caps worth more than US $ 1 billion.

Better future ahead with technological innovation and advancement

Top brands selling in India are mostly dependent on imports. Though being a manufacturer, India has imported caps worth around US $ 25.26 million in 2022-23 which is 37.19 per cent higher in comparison to US $ 18.41 million imported during 2021-22. China has been on the top when it comes to caps’ export in India at US $ 13.79 million and a growth of 25 per cent. Similarly, Bangladesh’s caps exports to the country has been US $ 4.54 million with a growth of 45 per cent.

Even a company like Decathlon, which takes pride in ‘Made in India’ and for whom India is the fourth largest sourcing country, is facing challenges for caps sourcing. In India, it has very limited suppliers which have good manufacturing capabilities for cap manufacturing. Apart from capabilities, the common challenges that it faces are also linked to skills, advanced manufacturing, efficiency and ability to undertake technical developments.

With promising future opportunities in this segment, Decathlon is looking for suppliers which are willing to work with the company with a strong mindset of transformation linked to sustainability, automation, operational excellence and with the ability to invest in future trends and technologies.

“We want to push strongly for local manufacturing especially to reduce lead time and the environmental impact of Co2 on a product, be more affordable ensuring we have the best quality caps made in India The most important quality parameters for us in a cap are performance, functionality, durability and aesthetics. Hence we need to ensure that suppliers have very clear quality standards, right machines and skills to meet our requirements,” said Dinesh.

The majority of caps, of Columbia and BUFF brands, that are being sold in India are sourced from Vietnam, Indonesia and Spain and not from China.

“Features of the caps and quality are key for us and the caps we offer are much differentiated than what is offered in the market. This sets us apart and thus we can charge some premium from the customer. Also, this is helping us to grow this category very fast. Our target customer values quality and features and seeks premium products,” informed Ankit.

The brands are facing challenges in sourcing from overseas as the lead time from order placements till receiving the stock is very high in case of caps as most of them are imported.

To overcome the challenge of high lead time in importing caps from overseas, brands and retailers forecast the demand as accurately as possible by using different tools and techniques. They ensure to book it well in advance as per the cut-off dates. “We also keep some open-to-buy (OTB) relevant merchandise from the ready stock to respond to changing trends,” said Ankit.

Bhavisha Dave too endorses this issue as she stated, “We import since we are retailers of authentic streetwear brands. So as part of their offering, there are accessories, mainly headwear but yes we have not yet ventured into headwear manufacturing on account of good quality manufacturing which should be at par with what is provided by the international streetwear brands we house.”

This scenario is indeed an opportunity for Indian cap manufacturers to grab the share by offering world-class products. Apparel manufacturing inherently is a labour-intensive process, baseball caps more so. China has seen factory wages rise sharply in the past, hence Indian-made caps have become cost-competitive for export customers but in a few segments, quality is a major difference, especially in the premium caps segment.

| Caps have plenty of characteristics like antimicrobial, antibacterial and they have built-in inner bands to wick sweat and moisture away, UPF 50, certified sun protection against ultraviolet (UV) radiation produced by the sun. |

Vivek Khanna said, “A few factors like higher availability of skilled workers, deploying specialised automatic machinery, using raw material availability can help manufacturers to provide similar quality like that in any other country.”

In-house facilities for fabric bonding, embroidery and various printing techniques allow Sambhav Cap Creations to have manufacturing process which is both cost-effective and faster. The company dedicated on-the-job training to workers to upskill them and uses specialised machinery attachments.

Vivek also underlined that there is a need to improve the supply chain for specific components, especially those which meet international quality standards.

At the same time, investment in state-of-the-art infrastructure can be instrumental to improve India’s offerings as high tech machines are available for various operations of cap manufacturing.

| Most good quality caps are made with breathable fabric and also focus on sustainability. Some of the caps can be used for both everyday errands and hiking or tail adventures, as they are lightweight with quick-dry fabric and moisture-wicking features to keep the wearer cool and dry. |

Not just a ‘simple’ cap

Compared to garments, caps might look small; however, it is twice as difficult to put together a cap and operations can go up from 12 to 58 depending on the intricacies involved. A regular baseball cap includes at least 10-12 operations starting with cutting of fabric, followed by stitching of the crown and visor, embroidery on the panels, attaching eyelets on the panels, attaching tapes, making the visor part (alongside the crown, the front visor is made by stitching two fabric panes like a pocket and turning it inside out), attaching the visor to the crown and stitch, attaching sweatband, attaching cloth snaps (button), attaching closure (at the back of the cap) and finally ending with steaming the stitched cap.

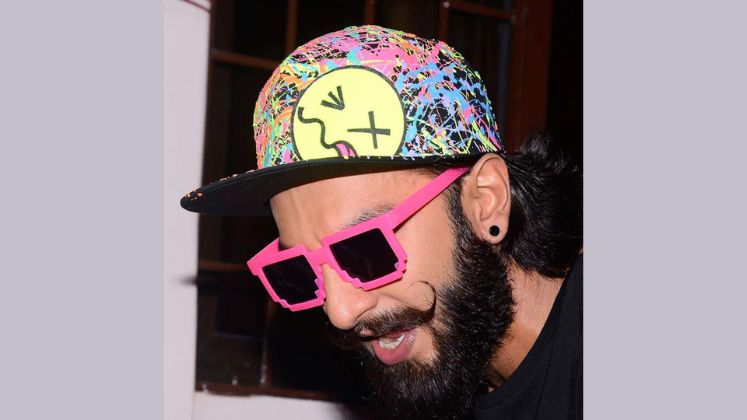

Good caps are a combination of aesthetics, features and technology. There are baseball caps with fashion-focused sequin blocks, rhinestones, all over-embellished pattern with colours ranging from nude pink, baby pink to prints like peach mini print. Most of the brands also offer unisex caps.

BUFF caps usually have more than 76 per cent-90 per cent recycled content to reduce carbon footprint. In particular, they are made with recycled plastic bottles with antibacterial fabric treatment and a seamless finished product (stitch-free finished product), which is also ultra-stretchable.

360-degree open mesh upper keeps user cool in the warmest of climates; an ultra-light fabric combined with a moisture-wicking sweatband keeps the user extra dry.