As fashion and apparel businesses get up on their feet post the COVID-19 lockdown, the tenets of hygiene and sanitisation, touchless operations and social distancing will become critical pillars of workspace planning and management for years to come. All these norms have been made mandatory by the Indian Government today; therefore, a huge inclination of garment business owners can be seen towards adopting solutions for the same, all because the technology companies – under Atmanirbhar Bharat concept – showed no reluctance to come up with exactly what the industry needs.

The efforts of Flipspaces, in collaboration with Magnum Resources, to reboot workspaces, are quite significant. The company has launched a suite of services and products for workspace transformation (for both factories and offices) called REBOOTSPACES. A typical garment manufacturing factory, undoubtedly, contains too many unsafe zones, right from raw material procurement zone to dispatch area, with no scope of social distancing as no proper layout planning is done before setting up the entire premises. The number of such factories is too huge in India to even count and that’s why the need for rebooting factory spaces is significantly high, especially in COVID-19 times.

Rebooting a space involves identifying the risk factor of various areas inside the factory premises and suggesting cost-effective measures to de-risk the same.

How does REBOOTSPACES work?

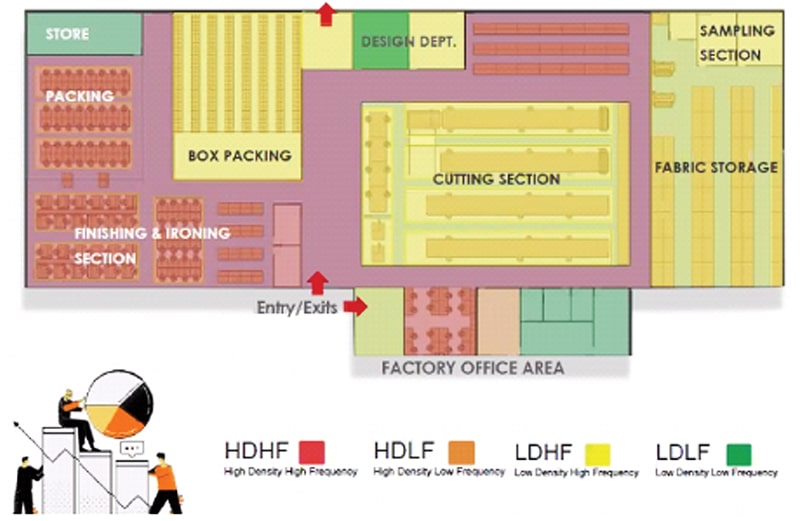

Firstly, a garment factory is asked to submit its layout by the REBOOTSPACES team based on which the entire premises is bifurcated into four zones on the basis of its user density and usage frequency as below:

Below are some observations/reasons made while bifurcating the zones according to colour codes (Refer to Figure 1):

- Reception: The reception is a ‘low density high frequency’ area with the visitors frequently pouring in.

- Office Area: Office admin and merchandise area is a ‘high density high frequency’ area wherein cabins are ‘low density low frequency’ zone.

- Design Department: This zone carries multiple functions wherein some space types are frequently accessed, while others maintain low frequency, but for a major part, the density of people using these areas remains high.

- Cutting Section: This zone has frequent movement in and out wherein type of work comparatively involves low number of workers.

Figure 1: Existing Factory Layout and Zone Identification according to Colour Coding by Flipspaces

- Fabric Storage: These areas, in a garment factory, are humid in nature; though visited by a less number of people or sometimes a designated staff remains there, it will be counted infrequently visited space type, making it a high risk zone.

- Sewing Section: The sewing area is one of the most highly occupied areas on the factory floor with the staff and operators sitting very close to each other. Also, the passage always has people moving around as well as the amount of fabric and garments all over the floor makes this space humid in nature that can carry infected droplets for long. Therefore, this is a ‘high density high frequency’ zone.

- Finishing Area: This particular zone has a significant number of people working too close to each other. Mostly, this area is only on the sewing floor, therefore making it one of the high risk countable zones.

- Packing & Dispatch: Packing area requires a lot of precautions and measures for safety. Even though the number of people working will be few, they remain in contact with many surfaces for longer durations.

In a nutshell, Table 1 below mentions bifurcation of the parameters as per the zones:

Table 1: Zonal Bifurcation

| S. No. | Parameter | Full Name | Colour Code | Bifurcation of Zones |

| 1 | HDHF | High Density High Frequency | Red | Merchandise Room, Sewing Floor, Checking, Finishing and Ironing Sections |

| 2 | HDLF | High Density Low Frequency | Orange | Conference Room, Training Room |

| 3 | LDHF | Low Density High Frequency | Yellow | Fabric Storage, Sampling Room, Cutting Area, Embroidery |

| 4 | LDLF | Low Density Low Frequency | Green | CAD Room |

Once the coding is done on existing layout, AI-based technology of REBOOTSPACES applies social distancing guidelines with proper safety measures in action with which a fair number of around 60 per cent workforce can continue working back in the factory. The main focus of rebooting the space remains on Red and Orange colours which are converted into Yellow and Green colours.

According to Lalit Khosla, GM (Operations), Industrial Sewing Machine Division, Magnum Resources, the use of AI senses the entire plant layout to recommend social distancing guidelines as well as safety and sanitisation equipment to be used in every zone within the factory. “Here come our solutions, made entirely in India, which are recommended to implement in different factory areas for structural reboot as well as to ensure safety and social distancing,” explained Lalit.

As far as social distancing equipment are concerned, REBOOTSPACES offers various products which include modular partitions, partition screening, reception table isolator, sofa isolator, table isolator, signage and graphics. On the other hand, for sanitisation and hygiene, the products include air curtain, foot operated liquid dispenser, automatic liquid dispenser, Hepa-filter-based air purifier, shoe cover dispenser, gloves dispenser and face mask dispenser.

“Not just inside zones of a factory, but the outer areas such as parking and goods carrier area have also been taken care of. One of the recommendations from our side includes sanitisation of every truck/vehicle carrying the goods and entering the factory in order to ensure every material or consignment entering the facility is sanitised and is safe for utilisation,” further shared Lalit.

This is how guidelines and new layout look like once REBOOTSPACES ropes in its expertise:

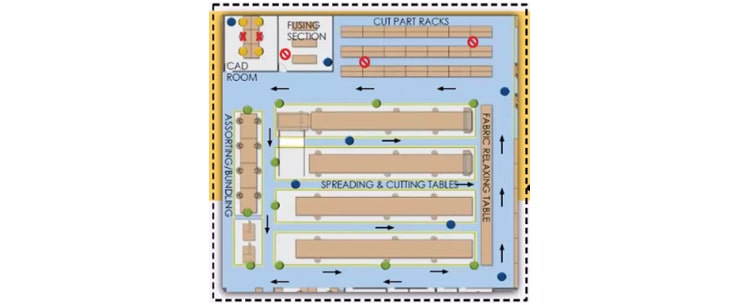

As it is already mentioned above that every department/zone is taken care of in two ways – 1) social distancing and 2) sanitisation and hygiene, here is one pictorial example of how this is ensured in cutting area.

- Social Distancing:

In this above picture (rebooted layout with recommendations), one can see a lot of markings of different colours – red, yellow, green and blue. The meaning of these markings is mentioned below –

- Red round sign denotes ‘Restricted Entry’ at 3 different places

- Cross red sign denotes ‘Seats Not In Use’ at 2 different locations within the cutting room

- Green round sign means ‘Modular Partitions’ are required at 11 different locations

- Yellow round sign means ‘Partition Screening’ is required at 4 locations

- Blue round sign denotes ‘Signage and Graphics’ need to be pasted at 7 locations

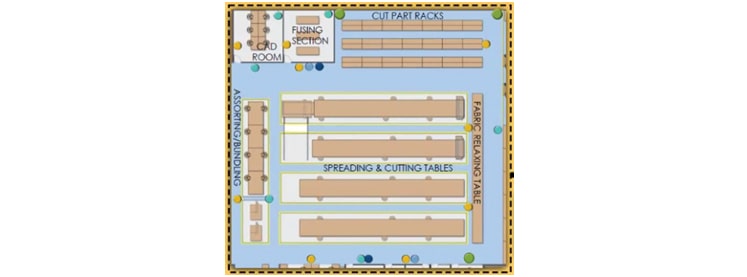

- Sanitisation and Hygiene:

As far as sanitisation and hygiene recommendations are concerned, the various markings and signs have following meanings –

- Yellow round sign denotes the need for ‘Foot Operated Liquid Dispenser’ at 9 different places

- Aqua Blue round sign denotes the need for 6 HEPA-filter-based air purifiers

- Sky Blue round sign means 2 ‘Glove Dispensers’ are required in cutting room

- Dark Blue round sign means 2 ‘Face Mask Dispensers’ are required

- Green round sign denotes ‘Dehumidifier’ needs to be installed at 3 locations

Therefore, recommendations are given to all zones/departments by studying their respective needs.