Success stories of Total Productive Maintenance (TPM) implementation in automobile and ancillary equipment industry have eluded identical resonance from the apparel industry. Benefits of quantifying maintenance performance in terms of ‘Productive Maintenance’ [Overall Equipment Effectiveness (OEE), StitchWorld February 2011], is yet to percolate in the needle trade, feels Chandrark Karekatti, an industry consultant. Based on his experience on lean implementation, he suggests that the apparel industry is yet to mature beyond planned and preventive maintenance. This disparity in the needle trade is mainly on account of traditional operational systems that barely plan beyond delivery schedules. The article is an attempt to assess, design and analyze the benefits of autonomous maintenance procedure for apparel manufacturing industry.

‘Maintenance’ is still perceived to be a cost centre and the focus is on minimizing maintenance cost rather than overall organization performance. Additionally, TPM implementation requires trained manpower as under-trained technicians can cause more damage than they can prevent. The firefighting environment in apparel industry also makes it practically impossible to think beyond quick fix solutions for maintenance function. In such a scenario, it is necessary to investigate the utility of easier and technically less demanding TPM tools, till the time factory matures to inculcate the intricacies of TPM philosophy.

Understanding Equipment Deterioration

Understanding Equipment Deterioration

It is a known fact that poor maintenance practice leads to equipment deterioration, hence to arrest the equipment deterioration, it is necessary to arrest the causes for equipment deterioration. Among the two kinds of deterioration processes, the Natural deterioration can be addressed through preventive and predictive maintenance procedures which are aimed to extend useful machine life, whereas the other deterioration process, Accelerated deterioration, can be addressed by implementing Autonomous maintenance, which aims to establish basic machine condition (restoring machine condition before major maintenance defects cave in). While the preventive and predictive maintenance procedures require careful planning, scheduling and deployment of skilled manpower, the Autonomous maintenance is not high on resource and skill requirement and can be carried out with existing shop floor workforce.

Purpose of Autonomous Maintenance

Purpose of Autonomous Maintenance

Autonomous maintenance is a new maintenance philosophy where basic maintenance activities are performed by operators themselves. These activities are aimed towards establishing basic machine condition through cleaning, oiling, retightening and inspection. Such activities prevent accelerated deterioration of equipment and hence minimize minor equipment defects (Exhibit 1.4 lists identified minor equipment defects for sewing machine that can lead to accelerated equipment deterioration). It is observed that even when maintenance procedures are followed, equipment reverts to systemic failure, if basic maintenance instructions (early detection of minor machine defects) are not adhered. It is observed that the process of capacitating operators in operating, maintaining and repairing the machines, develops a sense of ownership among machine operators. Reduction in machine tampering incidents is another major benefit of implementing autonomous maintenance. Tampering of programmable data/display board, tampering of machine mounted LED/ CFC light and light stand, needle guard tampering, bobbin winder damage, SPI regulator tampering, edge cutter tampering, etc. are some of the tampering incidents observed in sewing operations. In fusing section such incidents observed are damage to conveyer belt, tampering of temperature and pressure gauge etc.

How Autonomous Maintenance Works

Autonomous Maintenance prepares operators to perform some basic maintenance activities such as inspections, cleaning and small adjustments. They are supported by a team of engineers, technicians and managers who work together for maintaining the machine. Autonomous Maintenance helps operator in developing ability to recognize abnormal operating conditions. They are then trained to perform routine checks and minor maintenance tasks while freeing up maintenance personnel for predictive and preventative maintenance activities. Autonomous maintenance also called as CLIT (clean-lubricate-inspect-tighten) is a five minutes basic maintenance procedure performed daily by operators and is aimed at restoring the machine condition.

Case of Autonomous Maintenance in Apparel Industry

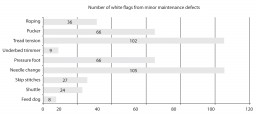

To know the scope of implementing Autonomous maintenance, stratified quality data for end of line inspection was analyzed (Refer Exhibit 1.1). Analysis revealed that oil stains, soiling and loose ends were some of the major causes (that can be addressed through Autonomous Maintenance) contributing to defects at sewing stage. These defects can be significantly minimized by designing appropriate checkpoints in autonomous maintenance checklist(Refer Exhibit 1.4). Further, for pilot sewing lines, stratified data regarding frequency of minor maintenance flag (white tag) posted was analyzed (Refer Exhibit 1.2). Analysis of data revealed that for a significant number of times, the sewing mechanic attended issues pertaining to thread tension, pucker, needle change, skip stitches, etc. Thus by training operators to handle these basic adjustment, they can be capacitated to handle minor maintenance activities thereby freeing mechanics for specialized maintenance function. However, to capacitate operators in handling needle change procedure, it is necessary to simultaneously train them on Quality Management Systems such as metal policy, broken needle policy, etc.

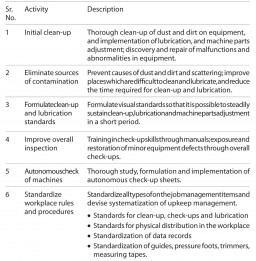

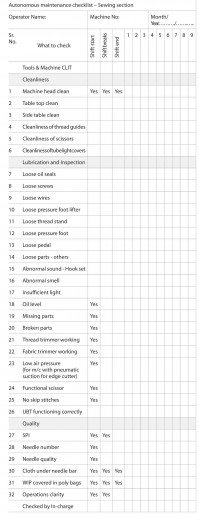

Developing Autonomous Maintenance Procedure

It is necessary to develop separate autonomous maintenance checklist for each type of machines. The checklist should take into consideration the specific maintenance requirement that can be handled through it. Exhibit 1.3 shows generic list of activities that an autonomous maintenance checklist should cover. Exhibit 1.4 shows an autonomous maintenance checklist developed for sewing section. Operators are expected to perform activities described in checklist, selectively as per the activity time (shift start, break, shift end, etc.) mentioned in the checklist. The line supervisor should check the filled in checklist daily and highlight the abnormalities to the maintenance supervisor. Minor maintenance defects are just basic defects that can be addressed by machine operators through basic maintenance training. As a thumb rule, minor maintenance activity should not extend beyond cleaning, lubricating, inspecting and retightening. However, each factory should identify (based on shop floor capability) list of minor machine defects that can be addressed by machine operators. Typical example of minor defect is pucker, which can be addressed by thread tension regulation. The operator flags these minor defects with a white tag (Refer Exhibit 1.5), till the time they are not resolved. These defects are disposed (resolved) by operator himself/herself (if required with the help from maintenance personnel). It is recommended to follow the tagging procedure, since it helps in creating awareness on shop floor and also helps in keeping track of abnormality resolution. Sustainability of such initiatives can be ensured by auditing their conformance periodically. Other major maintenance defects/breakdowns are marked by red tag and disposed (resolved) by the maintenance team.

Effective Asset Management with FAMS

In an industry where effective utilization of resources has become very critical to save time and money, keeping track of fixed assets at different locations and various stages of deployment is equally important. Supporting this endeavour is FAMS (Fixed Assets Management System) from the house of ISSS (Industrial Soft Solutions & Systems) under the leadership of A. Ravee Parthasaarathi. Propelled by barcode technology, this unique system not only helps in keeping track of fixed assets (both movable and immovable) but also ensures that the same is effectively used and optimal performance is driven from the assets.

[bleft]Autonomous maintenance is neither a high management theory nor a high investment tool and can be carried with existing shop floor manpower. When implemented fully, autonomous maintenance has potential to improve productivity, quality and reduce cost. It would be interesting to study the impact of autonomous maintenance implementation on productivity, quality and profitability of an apparel factory on a larger scale.[/bleft]

In a busy work schedule, more often than not industrial engineers, factory managers, accountants, maintenance engineers focus only on their individual areas of responsibility, losing out on the need to collaborate for optimum utilization of assets. FAMS helps in creating visibility in the system so that all departments at every location are on the same page, eliminating duplication of work and fostering collaboration throughout the organization.

Gaining information and knowledge not only about your assets but also where they are and in what condition helps plan production in advance, and along with easy audit of machines, spare parts, valuable fixtures and other assets, provide savings of around 20% on new purchase costs through informed knowledge of existing machines and their performance.

Machine maintenance is not only about periodical and preventive maintenance, but also about documentation of manuals, parts book, invoices, etc. in the course of several years and going through several management changes. FAMS helps in realization of higher value of assets instead of selling them at scarp value.

Since each asset is tagged with a unique ID called as ‘asset number’, there is no chance of misrepresentation and any authorized person can check at any point of time 24/7 where the resource is and make critical decisions with full transparency on where to use the said asset. It has been found that manual stock keeping is ineffective and fails to prevent pilferage, wastage and theft. However, with all assets tagged, they are on the management radar at all times and cannot be misused or appropriated in any way.

Through better documentation of assets with manuals/part book/supplier details, the management can better analyse performance of machines in terms of supplier/service provider and deal with them with data and facts for rapid return on investment. Money savings also comes by avoiding maintenance/insurance/AMC costs on redundant and unused assets, through sharp and updated knowledge of condition of each asset.

The audit process is in two steps: Firstly, a unique barcode will be assigned and fixed to each asset/machine and also to each location. After this the auditors scan the asset location and individual assets one by one. After the scan is completed, all the data is stored in the system for processing. It is only after receiving confirmation of the data on the screen, the audit will be complete at that location. This process will continue at all locations which are given to audit; and after all the data is collected, the same is corroborated to find out miss-match and missing assets.

The audit process is in two steps: Firstly, a unique barcode will be assigned and fixed to each asset/machine and also to each location. After this the auditors scan the asset location and individual assets one by one. After the scan is completed, all the data is stored in the system for processing. It is only after receiving confirmation of the data on the screen, the audit will be complete at that location. This process will continue at all locations which are given to audit; and after all the data is collected, the same is corroborated to find out miss-match and missing assets.

Similarly when machines are transferred from one factory to another the asset/machine has to be scanned at the security gate, after which the asset/machine will be shown as in transit. Once the asset/machine reaches the destination factory, the asset has to be scanned again at the security; only after this the asset/machine will be transferred as the asset/machine of the destination factory for record purposes.