Growing competition from emerging manufacturing destinations is forcing apparel producers to look for tools to achieve dramatic improvements in process performance. Many manufacturers have already initiated the Six Sigma Implementation for process improvement and many more are desirous of implementing the same. In the absence of knowledge on implementation methodology in public domain, many Six Sigma initiatives in apparel factory have delivered unsatisfactory results. In this article, the third and the final in the series of Quality Management Systems (QMS), Team StitchWorld attempts to demystify the implementation methodology of Six Sigma system and also deliberates reasons of its poor implementation in the needle trade.

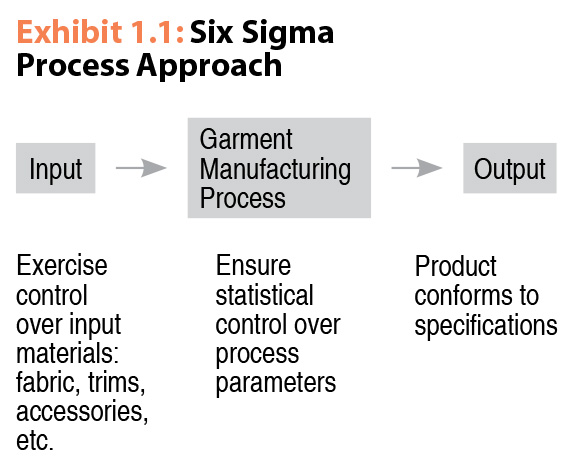

Unlike the product inspection-driven approach of conventional quality control processes, Six Sigma methodology has a process-based approach. The methodology ensures that the finished garments conform to required specifications by exercising control over input materials (fabric/trims accessories) and ensuring statistical control over process parameters (Refer Exhibit 1.1). One of the reasons of failure of Six Sigma system in apparel industry is lack of understanding on utilizing this system in process transformation. Conceptually, Six Sigma system is designed to bring drastic breakthrough improvements (targets 3.4 defects per million opportunities or straight through level of 99.9997%). Hence, many tools in Six Sigma tool kit are aligned to deliver drastic process improvement. This very requirement makes them complex and time consuming. With most of the garment factories operating at defect percentage of 5-7%, apparel manufacturer should judiciously select the tools based on their individual requirement. They should also refrain from using all the tools at a time.

It should be noted that tools such as Measurement System Analysis (MSA), aimed at bringing repeatability and reproducibility of testing and measurement processes are of very little significance in an apparel factory. Moreover, tools such as Failure Mode Effect Analysis (FMEA) that aim at minimizing potential failure modes may not prove to be effective in an apparel factory where more emphasis is needed on minimizing the existing failures than on eliminating the potential failure modes. The perception that Six Sigma is not necessary for garment manufacturing is not completely unfounded, since it aims to achieve 99.9997% accuracy or almost zero defects, which may not be an immediate requirement of needle trade. However, even if the company does not reach Six Sigma levels, the company will be able to improve process consistency significantly through Six Sigma journey.

Six Sigma defined

In layman’s terminology Six Sigma is a set of techniques for process improvement and seeks to improve the quality of the process by identifying and removing the causes of defects (errors) and minimizing variability in business processes. It uses a set of quality management methods, mainly empirical statistical methods, and creates a special infrastructure of people within the organization (‘Champions’, ‘Black Belts’, ‘Green Belts’, ‘Yellow Belts’, etc.) who are experts in these methods.

Six Sigma Implementation Methodology

The DMAIC (Define Measure, Analyse, Improve and Control) method used for implementing Six Sigma initiatives pertaining to existing products and processes is derived from Deming’s Plan-Do-Check-Act Cycle. Team StitchWorld with its experience in implementing Six Sigma projects in apparel industry has identified following important tools in each of the DMAIC phases that suit the exacting requirements of low technology and labour-intensive nature of the apparel industry:

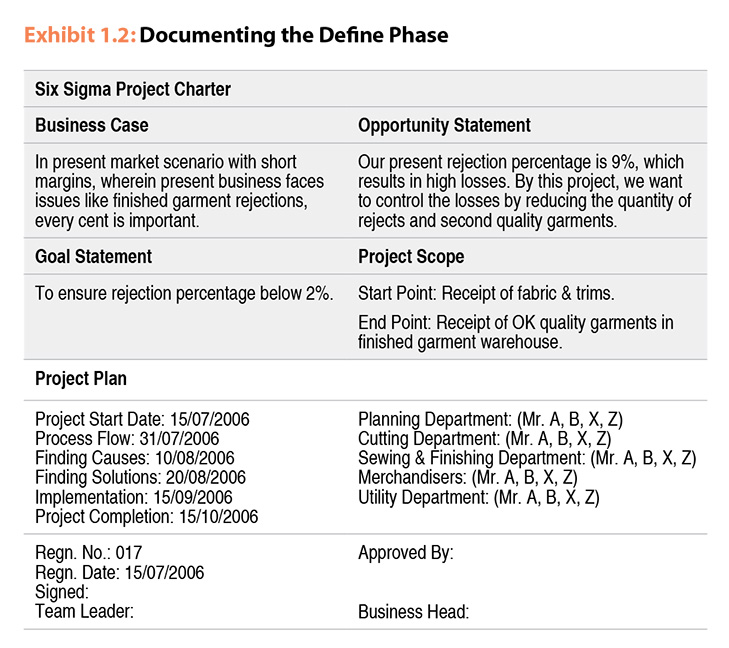

1. Define Phase: This forms the foundation phase in Six Sigma initiative. It lays down the premises of the project initiative. The key components of the Define Phase are – project title, project scope, team charter, quantifiable goals and target completion date. (Refer Exhibit 1.2). It is advisable to formulate a cross function team, comprising process owners/ senior managers from concerned departments that are related to the project scope.

2. Measure Phase: This phase is associated with data gathering and data stratifying to draw valuable information needed for Analyse Phase. Key tools that are found very effective in this phase are:

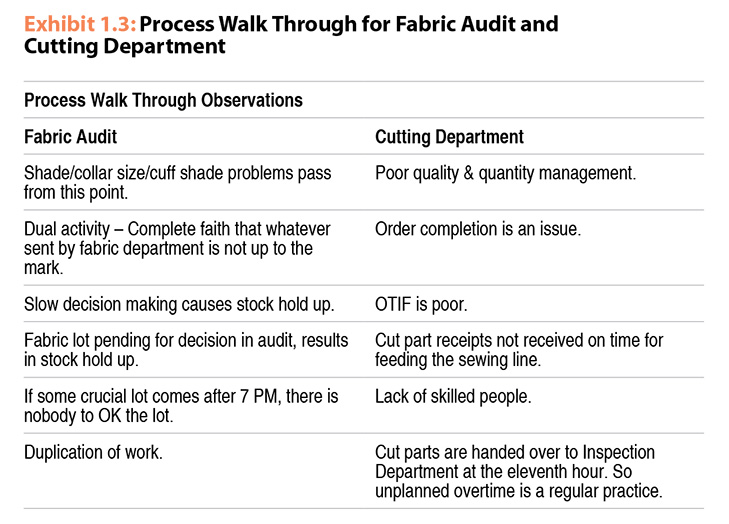

a. Process Walk Through: This tool is very important in throwing light on abnormalities that escape eyes as over a passage of time employees tend to become blind to them. The Process Walk Through should be carried out number of times, by practically tracing the material path and identifying the existing visible abnormalities in the process (Refer Exhibit 1.3).

b. Needle Time Data: This tool gives an idea on to what extent the operations deviate from standard needle time (approx. 20%).

1. Inventory and Line WIP data.

2. Machine down time report.

3. Hourly production and quality data (Cutting, Sewing and Finishing).

4. Fabric inspection reports.

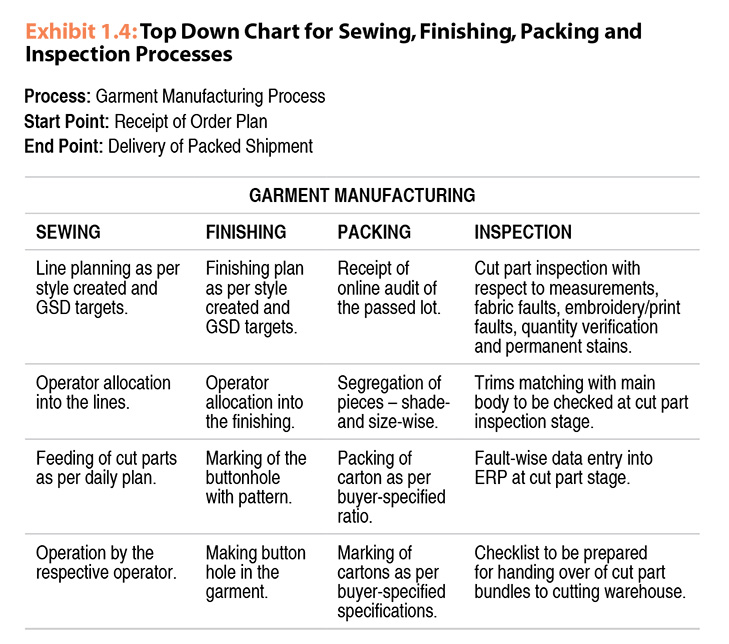

c. Top Down Charts: These charts help in understanding the present flow of material through various processes. They are used as a basis to design a better process during the improve stage (Refer Exhibit 1.4).

d. Final Audit Reports: Carton Audit Reports and Final AQL Failure Reports.

3. Analyse Phase: This phase is associated with deciphering the data collected to understand the general trend or main cause of the abnormality. The key tools that are of importance in this phase are Trend Charts, Pareto Charts, Fishbone Diagram, SIPOC with indicators, Cause and Effect Matrix and Five Why Analysis.

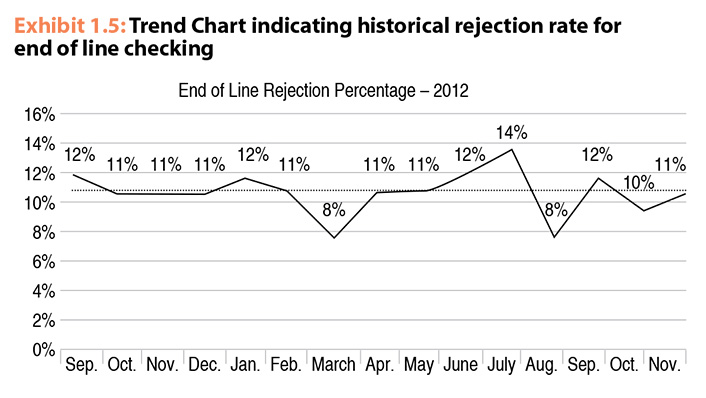

a. Trend Charts: These charts give an understanding on cumulative trend of the target parameters (quality, production, etc.). They are very helpful in understanding the historical performance to arrive at base line figures (Refer Exhibit 1.5).

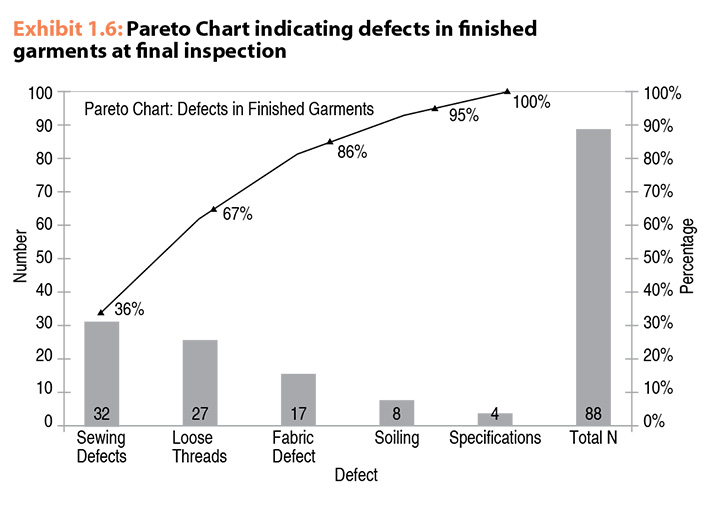

b. Pareto Charts: These are one of the most important analysis tools that help understand vital factors contributing to failures. The tool is used to eliminate trivial issues and target only few vital events that predominantly cause the failure. For example, Exhibit 1.6 shows sewing defects and loose threads contribute to more than 80% of total finished garment defects. It enables in making subsequent action plan for addressing these vital causes.

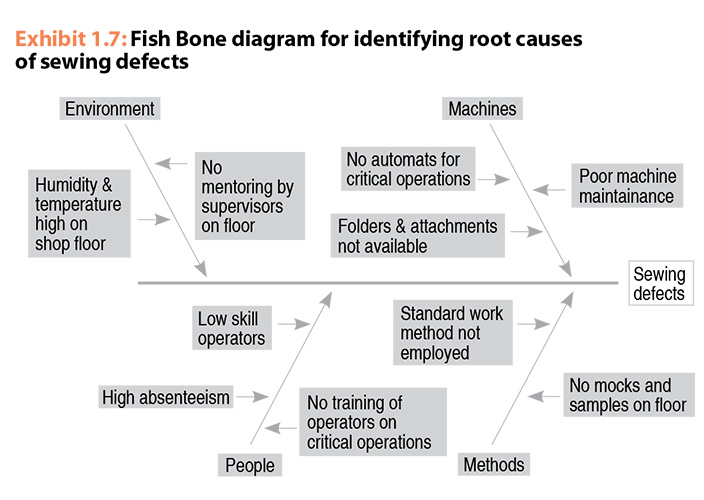

c. Fish Bone Diagrams: This tool helps in identifying the root causes for an abnormality. This step is used to find root causes for vital parameters as identified in the Pareto Analysis (Refer Exhibit 1.7).

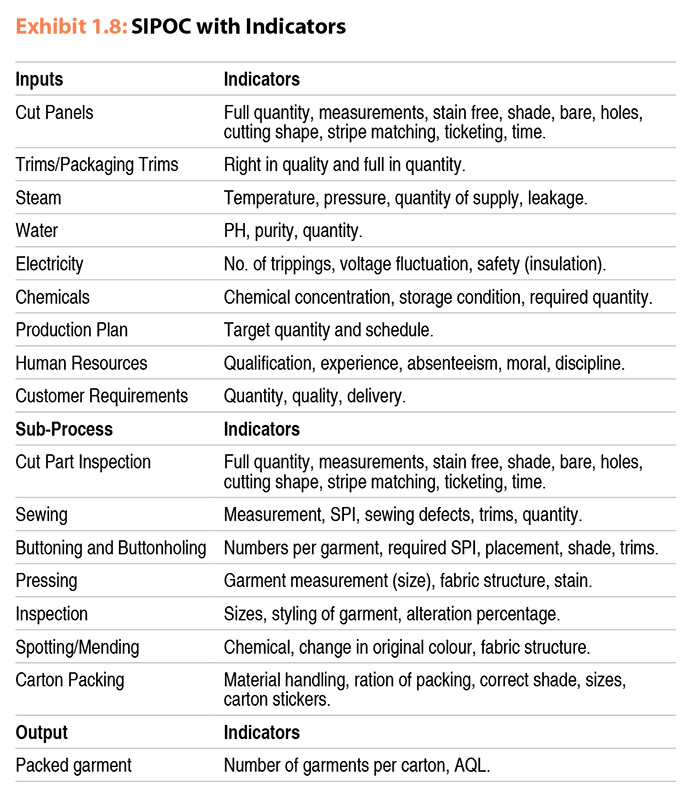

d. SIPOC (Supplier Input Process Output Customer) with indicators: It is a tool used to identify the input parameter requirements for satisfactory performance of the processes. As indicated in Exhibit 1.8, for each input parameter quantifiable indicators are noted. The shortcomings in these input indicators are worked upon during the Improve Phase.

4. Improve Phase: The Improve Phase basically decides on the most appropriate solution for identified problem and implementing the solution in a time bound manner. The most important tools used in Improve Phase are:

a. Brainstorming: It is a powerful tool for generating as many ideas or solutions as possible to a problem. It is not a tool for determining the best solution to a problem or issue. The exercise should be done with the entire cross functional team to ensure ideas and views of all stakeholders are captured. Brainstorming creates new ideas, solves problems, motivates and develops teams.

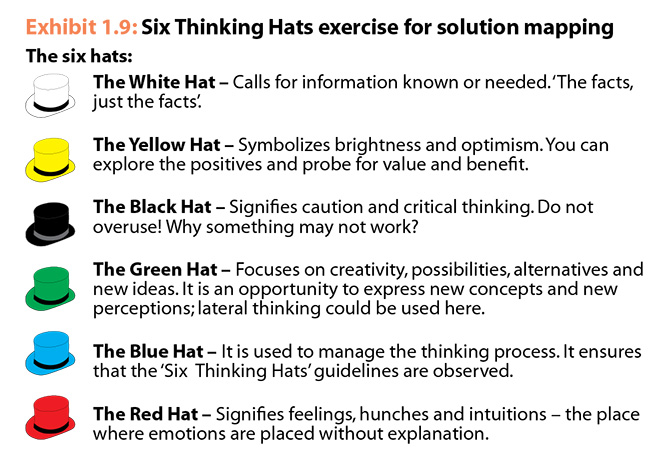

b. Six Thinking Hats: The brainstorming process helps in gathering possible solutions to a problem. These possible solutions are used as inputs for Six Thinking Hat exercise. This tool helps in identifying most appropriate solution from various solutions identified during brainstorming. The premise of the method is that the human brain thinks in a number of distinct ways which can be deliberately challenged, and hence planned for use in a structured way allowing one to develop tactics for thinking about particular issues (Refer Exhibit 1.9). It is also observed that in most groups, individuals tend to feel constrained to consistently adopt a specific perspective (optimistic, pessimistic, objective, etc.). This limits the ways in which individual or a group can resolve an issue.

In Six Thinking Hats, participants are not constrained to single perspective of thinking. The hats are categories of thinking behaviour and not people themselves. The purpose of the hat is to direct the thinking and not classify either the thinking or the thinker. It is important that all the group members are aware of this fact before starting the exercise. Before conducting the Six Thinking Hats session, arrange chairs in a circle so all the participants are facing each other. The order of hats most suited to process improvement – White, Yellow, Black, Green, Blue and Red. This, putting on and taking off of hats is essential, as it allows participants to switch from one type of thinking to another. In a group exercise, all the participants should wear the same hat at the same time; this ensures parallel thinking so that all the participants are focused on and thinking about the same subject at the same time.

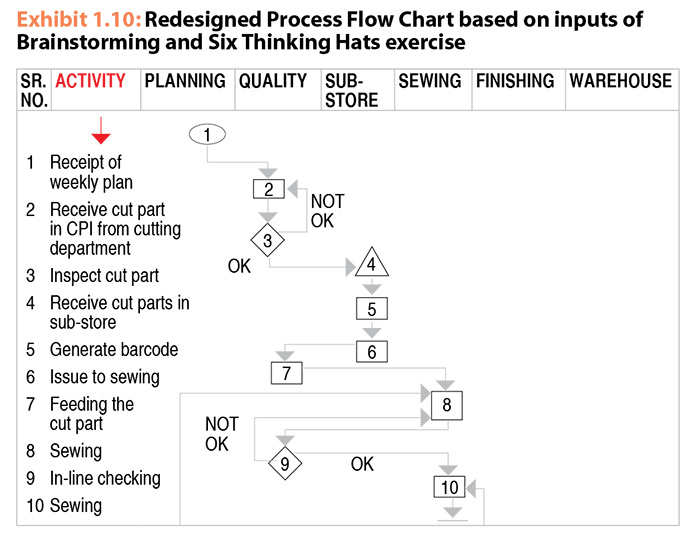

c. Revised Process Flow Charts: This tool is used for re-engineering the process flow based on specific solutions identified through the Brainstorming and Six Thinking Hats exercises. The Top Down Chart developed in the Define Phase is used as a basis to redesign the process flow system (Refer Exhibit 1.10).

Once the solution mapping is complete, it is important to work out a time bound action plan for implementing the selected solution. It is important to conduct periodic process audits to ensure that the changes incorporated are sustained.

5. Control Phase: The Control Phase forms the last part of the Six Sigma initiative. This phase is aimed at sustaining the improvements achieved through the Six Sigma initiative. The Control Phase encompasses converting the defined processes and procedures into standard procedures by means of SOP’s and work instructions. The shop floor employees should be trained on revised operating procedures and system before implementing the new systems. Periodical audits by process owner should be initiated to ensure that the process does not slip back to the original system.

Conclusion and Discussions: The article while articulating the step-by-step methodology of Six Sigma Implementation also describes important tools that are of importance, considering the labourintensive and low technology nature of needle trade. Adherence to these steps can be helpful in ensuring that the factory is following the Six Sigma principles productively.