Italian pioneer Vibemac has always been at the forefront of delivering automated sewing solutions to the apparel industry for jeans manufacturing. With around 4 decades of sturdy existence in servicing the global apparel industry, Vibemac has seen many milestones that have become benchmarks for raising the technological standards of the industry. Enrico Guerreschi, Global Sales Director, Vibemac and second generation of this highly innovative company, is the force behind the success of the company’s march into the Asian market. In an exclusive tête-à-tête with Team StitchWorld, Enrico unveils how he strategically executes the growth plans of his company and keeps Vibemac among the best in jeans automated solutions, despite competition from many quarters.

SW: In a company that can truly be called as the innovator of jeans manufacturing, where is your niche and personal contribution?

Enrico: We started Vibemac over 37 years ago and while my father was the brain behind the technology, I took up the marketing challenges. Sensing a huge potential in the export sector of India, I inclined myself toward this country 34 years before. In fact, India was my first market and, for me, it was no less than a launching pad. Once I strengthened my roots in India, I moved on to Bangladesh, Pakistan, Vietnam, and other countries of South Asia. My father used to take care of the America market while I was looking after the Asian market.

Frankly speaking, my career path is similar to every other salesman, as I used to travel from door to door and customer to customer explaining my product. I firmly believe that it was the happiest moment of my career as I was selling humour along with machines, in my search for better business opportunities. We still work in the same way. Over the years, this personalized approach has helped us to constantly reach out to new customers and retain old customers with us. We know all of them by name. From owners to production managers, I recognize everyone. In my life, I have seen sewing operators become Vice Presidents, so it’s important for me to continue my personalized relations with my customers.

SW: You have been promoting automation for a long time. Has this really reduced the sewing cycle time over the last decade; and in which areas is the difference noticeable?

Enrico: As a matter of fact, we tell people that Vibemac is one of the many brands in the market but actually the way we use technology in our machines is unmatchable. If I talk about India, it cannot survive without automation because of the lack of skilled operators in most of the areas. India is known for producing high-end garments and these garments need immense level of skills from the operators. But with such skills not so easily available nowadays, manufacturers need to rely more on automation. Also, human intervention will always increase the sewing cycle time, but over the last decade, the cycle time has reduced drastically because of the higher use of automation as observed by me.

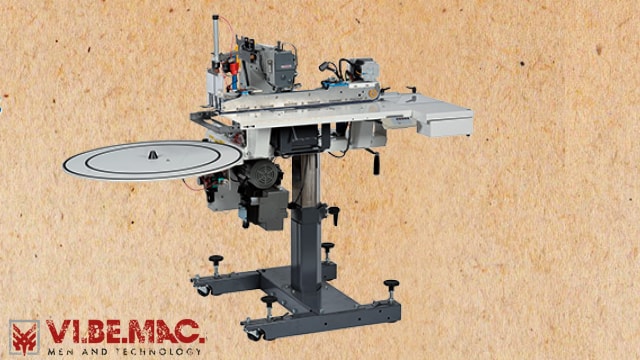

I, in fact, firmly believe the apparel exporters at present can’t avoid having automated sewing solutions for belt loop (in jeans) and pocket hemming machines in their production lines. Vibemac has already delved into this market with its self-developed machines We have been supplying these machines since the early, ’80s. By having such machines, a garment manufacturer can avoid the need of manual operations in jeans manufacturing. I mean they no longer need a worker who is continuously cutting the loops, while another operator keeps bending and stitching the loop and the process goes on, taking up a good amount of time.

Our machines have reduced SAM by 10 times. Yet, our objective is not to develop the fastest working machine but a flexible machine which keeps pace with the changing fashion and achieves quality standards which are impossible to reproduce.

SW: The V700 – double needle chain stitch that can be converted to single needle lockstitch, is one of your USPs…Why is it considered a quality feature?

Enrico: We are very proud of our stitch convertibility features. With our convertible feature, there will be no more wave effect or arching of the pocket hem problems during jeans manufacturing as we have incorporated pneumatic transport system which sees a belt that settles itself at the base of the fabric thickness and shape, plus an adjustable folder to satisfy every fashion need. And, to obtain the best possible results, we are using Yamato sewing head which is ‘Made in Japan’. Since stitching and fabrics constitute 70% cost of the garment product, our machines assist the garment manufacturers in saving cost of the machines.

SW: What is your take on human-less sewing line or sewbots? The classic five-pocket jeans is now a standard product. Why are there no further efforts done to make it completely automated? Is it possible?

Enrico: Yes, of course it is possible. People in the USA are already manufacturing garments using sewbots in completely automated lines. We have been performing hemming pocket operation through automat folders and we are the first ones to do this. But talking about India, though full automation is possible, we also need to see the practicality of the same since India is a labour-intensive country. Interestingly, the country has pockets and salaries of operators which differ from city to city.

Ahmedabad, Bellary, Delhi, Noida and Mumbai are using automation in jeans manufacturing but not on that grand level. The workers still majorly contribute in these hubs. Whereas, the people who already have great hands in automation in other parts of the world, are using just one operator on three machines simultaneously. So the cost of their production is 3 times less than that of India. This is why ROI in India is much higher. What is important to understand is that economy should be built on profit which is gained by the investment. So I always balance between things as, not just technology, but the time and location where the technology should be placed are important.

Change is happening and now even local producers in India are using small automations in their products as they know that without automation, they won’t be able to remain competitive for the next 5 years even in the local market. For them, both the cost and quality have become significant parameters to work on. If these people are using automation, then it’s a definite need for reputed brands to incorporate automated solutions in their jeans.

SW: What is your take on Industry 4.0 initiative?

Enrico: According to me, Industry 4.0 is just in the concept phase. There is a long way to go before it becomes a reality. People who talk about machine-to-machine communication have not yet seen the positive impact of these technologies. So, I seriously don’t know if it will be feasible in near future. I am not a great believer of this concept and frankly for me, it’s more of a hype than reality.

SW: There are some Chinese brands duplicating your models now…how do you react to such technology? Going forward, what’s the next direction of development?

Enrico: The market is huge and everybody is trying to penetrate the market in any way they can. Some companies copy technology and sell it in the cheaper markets. All Vibemac needs to do is to protect the brand name from this duplication with patents and that is what we are doing. In terms of development, we are actually pretty ahead of others. Whenever someone copies our technology, we are already in the market with something new. This is our specialty as we have already grabbed the premium garment market.

I believe 50% of the human body is covered by bottomwear that is jeans and the upper part can be covered by anything such as shirts, jackets and T-shirts. So, in my opinion, we need to focus on quality for that 50% part and we are doing the same also – manufacturing machines which produce ‘Classic Jeans’. All our developments are governed by this one thought.